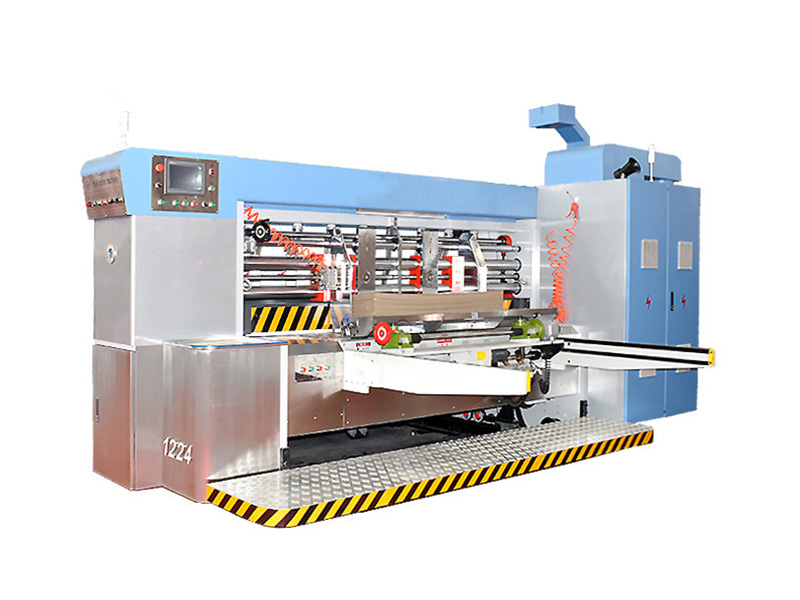

Automatic High Speed Corrugated Cardboard Flexo Printing Slotting Die Cutting Machine

Corrugated cardboard flexo printing slotting die cutting machine china factory

1. Source of goods manufacturer, 14 years of production experience and guaranteed after-sales service.

2. Competitive prices, factory prices, no links to trading companies.

3. Intelligent equipment is easy and fast to operate.

4. Automatic printing machine is the main product.

5. Customized according to customer requirements.

6. CE quality certification.

Share This Page

Function and Characteristic:

- Intelligent operation, multi touch screen control, all-round automatic adjustment and computer order management. (999 orders can be pre stored)

- The transmission gears of the whole machine are all made of 20CrMnTi alloy steel to ensure high color registration accuracy for long-term use.

- The accessories, electric components and pneumatic components of the whole machine adopt international well-known brands.

- The lubrication system of the whole machine adopts spray type automatic lubrication and is equipped with automatic balancing device

- The whole machine adjusts the preset position function, including paper feeding, printing, slotting, die cutting, automatic zeroing, and automatic reset of split memory.

- The main engine fan adopts frequency conversion control, which makes the startup and operation more stable and energy-saving.

The Machine technique parameter:

| Model | 2600×1200 | |

| 1 |

Color group |

to be configured according to user’s needs |

| 2 |

Printing paper |

A,B,C,A/B,B/C and A/B/C type corrugated paperboard

(the maximum interval 11mm) |

| 3 | Width of machine inside | 2600mm |

| 4 | Max.paper size | 1200×2400mm |

| 5 | Max.printing size | 1200×2200mm |

| 6 | Skip feeding paper | 1400×2400mm |

| 8 | Printing plate thickness | 7.2mm |

| 9 |

Design speed(piece/min) |

250pcs/min |

| 10 | Economic speed(piece/min) | 80-160pcs/min |

| 11 | Tinted precision | ±0.5mm |

| 12 | Slotting precision | ±1.5mm |

| 13 | Max.slotting depth | 7×300mm |

| 14 | positive knife

Min. Slot distance negative knife |

170×170×170×170mm

260×90×269×90mm |

| 15 | Max.die-cutting size | 1200×2300mm |

| 16 | Printing plate diameter

(contain plate thickness) |

ɸ405mm |

Paper feeding unit:

- Automatic air suction paper feeding, high speed and stable paper feeding.

- Suction frequency conversion adjusts the air volume to maintain the transmission stability and accuracy of warped paperboard.

- Double conveying roller structure.

- The position of left and right baffles and rear baffle box shall be adjusted electrically, and the side baffle shall be equipped with pneumatic snap device.

- Touch screen control, electric adjustment, one-time zero return, order storage, memory reset, constant speed cruise, photoelectric counting and other functions

- The host adopts frequency conversion control, which can save energy by 30%.

Printing unit:

- The printing roller adopts plate hanging device.

- Printing phase and axial adjustment: PLC touch screen control and electric digital 360 degree adjustment.

- PLC controls and adjusts the ink setting gap, printing press roller and paper guide roller.

- Erasing reset function, the computer remembers the printing position, and automatically resets after erasing.

- Anilox roller cooperates with paper feeding system and pneumatic lifting device.

- Equipped with ink shortage alarm device.

Slotting Unit:

- PLC and digital electric adjustment slot size, touch screen control.

- The slotting phase adopts PLC and electric digital input 360 degree adjustment, and the phase is controlled by motor frequency converter.

- The transverse movement of slotting cutter base and wire pressing wheel adopts synchronous electric adjustment. PLC touch screen adjustment, direct input carton size, automatic adjustment.

- Self locking structure is adopted for the adjustment of indentation clearance and cutter shaft clearance.

- The height of slotting cutter box is adjusted with anti-collision protection device.

- 6-axis device, equipped with prescoring wheel and wire scoring wheel.

-

Die cutting part:

- Rubber roller: centrifugal casting steel cylinder. The rubber pad adopts German brand.

- Die cutting roller: equipped with 4 slotted rings.

- Die cutting roller phase and axial adjustment, PLC touch screen control and electric digital 360 degree adjustment.

- The rubber pad roller is a cutting and repairing mechanism, and the rubber pad can be reused for many times.

- Differential compensation device can automatically adjust the number of revolutions of rubber cushion roll.

- The mechanical transverse ± 40mm swimming device of rubber pad roller improves the service life of die-cutting rubber pad.

-

Stacking unit:

- The height of chimney is 1600mm.

- The lifting of the platform is driven by chain, and the lifting motor has braking function.

- The platform automatically adjusts the tillage height.

- Set up safety protection devices to ensure that the platform will not suddenly fail and ensure the safety of workers.

- The corrugated belt on the surface can prevent the cardboard from sliding.

- Combined application design of chip removal brush and chip removal fan.

GET A FREE QUOTATION

Related Products