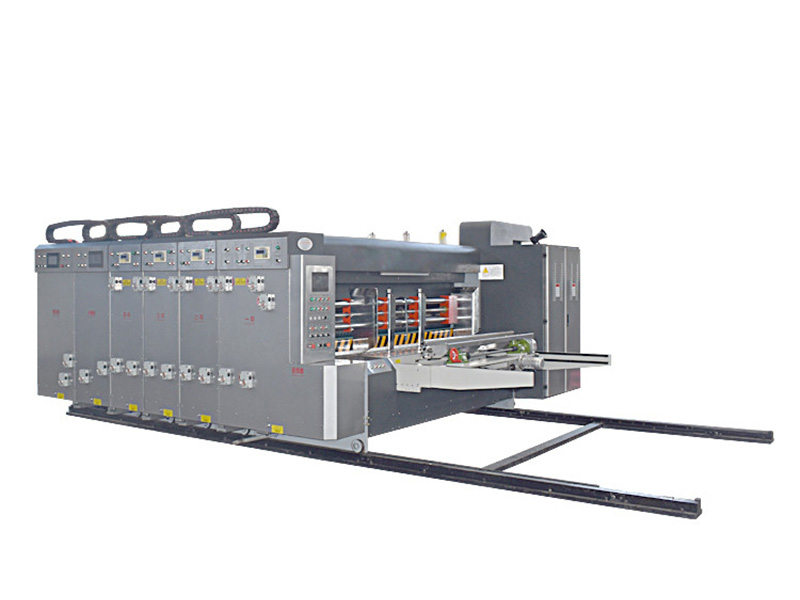

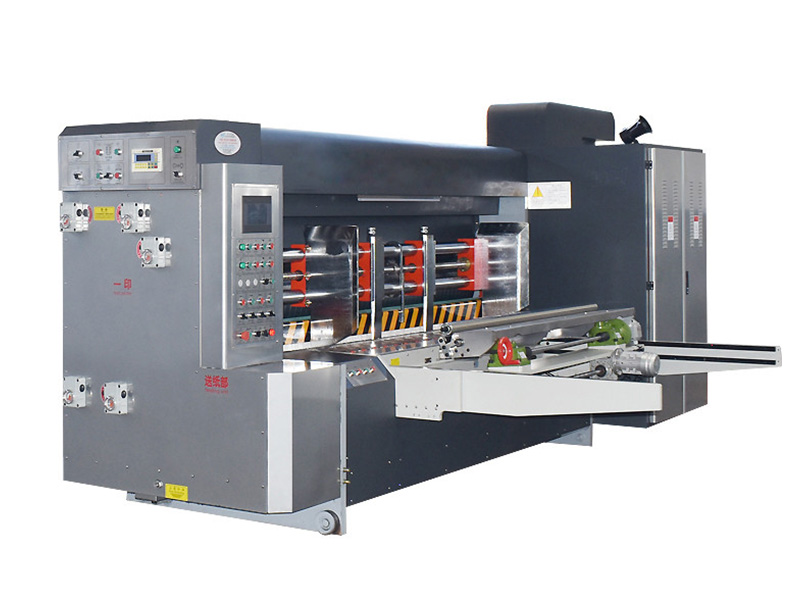

Flexo Printing Machine Manufacturer 4 Colors Flexo Printing Machine For Carton Box

4 colors flexo printing machine for carton box china suppliers

- Automatic paper feeding, medium speed machine, machine size can be customized

- Optional slotting part and die cutting part.

- Economical printing machine . Competitive price.

- Professional carton printing machine manufacturer.

- Perfect quality inspection system and after-sales service system.

- Multiple quality certification and honor certification.

Share This Page

Function and characteristic

- l electrical and pneumatic components are international famous brands with stable and reliable quality

- l all transmission gears are 40Cr.

- l the transmission parts (shaft and tooth joint) are keyless.

- l transmission bearings and important transmission components are famous brands in China.

- l the lubrication system of the whole machine adopts spray type automatic lubrication.

- l the main fan adopts frequency conversion control.

- l the cutting part of the circular die and the slotted part of the wheel are optional.

- l optional: ceramic anilox roller, stacker.

The Machine technique parameter:

| 1 |

Color group |

to be configured according to user’s needs | ||

| 2 | Printing paper | A,B,C,A/B,B/C and A/B/C type corrugated paperboard(the maximum interval 11mm) | ||

| 3 | Width of machine inside | 2600mm | 2800mm | 3000mm |

| 4 | max.paper size | 1200×2400mm | 1400 ×2600mm | 1600×2800mm |

| 5 | Max.printing size | 1200×2300mm | 1400 ×2500mm | 1600×2600mm |

| 6 | Skip feeding paper | 1400×2400mm | 1600 ×2600 | 1800×2800 |

| 8 | Printing plate thickness | 7.2mm | 7.2mm | 7.2mm |

| 9 | Design speed(piece/min) | 180pcs/min | 150pcs/min | 150pcs/min |

| 10 | Economic speed(piece/min) | 80-160pcs/min | 80-130pcs/min | 80-100pcs/min |

| 11 | Tinted precision | ±0.5mm | ±0.5mm | ±0.5mm |

| 12 | Slotting precision | ±1.5mm | ±1.5mm | ±1.5mm |

| 13 | Max.slotting depth | 7×300mm | 7×350mm | 7×400mm |

| increase the blade, increase the slot depth | ||||

| 14 | positive knife

Min. Slot distance negative knife

|

170×170×170×170mm

280×80×280×80mm |

170×170×170×170mm

280×80×280×80mm |

170×170×170×170mm

260×90×280×80mm |

| 15 | Max.die-cutting size | 1200×2300mmmm | 1400×2500mm | 1600×2700mm |

| 16 | Printing plate diameter(contain plate thickness) | ɸ405mm | ɸ480mm | ɸ530mm |

Feeding & printing unit

- The air suction auxiliary paper feeding fan is 7.5kW, and the air volume can be adjusted according to the different bending degree of the paperboard to ensure smooth paper feeding.

- The side baffle is adjusted electrically, and the front baffle and rear baffle box are adjusted manually.

- Seven inch computer touch screen control (display production volume, count alarm, phase adjustment).

- The brush dust removal device of the paper feeding department can remove a large number of impurities on the printing surface of the paperboard and improve the printing quality.

- Printing department: (1-4 color printing is optional)

- Printing roller: optional outer diameter: 300mm, 405mm, 480mm, 530mm.

- The outer diameter of steel anilox roller is ɸ 197.4mm (mesh: 180, 200, 220, 240, 260). (mesh optional) rubber roller: outer diameter ɸ 197.4mm。

- The anilox roller is attached with a wedge type overrunning clutch, which is convenient and fast in ink leveling and washing.

- The chequer gap dial is adjusted manually.

- Phase adjustment mechanism: printing phase electric digital 360 degree adjustment (both operation and stop can be adjusted).

Slotting unit

- The wire pressing wheel adopts French Martian Technology, which is hard and soft, straight and non explosive.

- The width of slotting knife is 7mm. Alloy steel material.

- The wire pressing wheel and slotting cutter seat are adjusted horizontally by electric adjustment.

- Slotting phase electric digital 360 degree adjustment (both operation and stop can be adjusted).

- Synchronous box height adjustment: Electric 360 ° adjustment, convenient and fast operation, and higher accuracy.

- The punching device can be optional as required.

Die cutting unit:

- Rubber roller: centrifugal casting steel cylinder. The rubber pad adopts German brand.

- The rubber pad of die-cutting roll adopts German brand.

- Die cutting roller phase and axial adjustment, PLC touch screen control, electric digital 360 degree adjustment.

- The rubber pad roller is a cutting and repairing mechanism, and the rubber pad can be reused for many times.

- The differential compensation device can automatically adjust the number of revolutions of the rubber buffer roll.

- The mechanical transverse ± 40mm swimming device of rubber cushion roller improves the service life of die-cutting rubber cushion.

GET A FREE QUOTATION

Related Products