5 Layer Steam Heating Corrugated Carton Cardboard Production Line

5 Layer Corrugated carton cardboard production line china manufacturer

- Professional manufacturer of corrugated board production line, with 16 years of manufacturing experience.

- OEM for international famous brands. Quality assurance.

- The production width is 1400-2500 mm.

- Heating methods include steam, electricity and heat transfer oil.

- It can produce 3/5/7 layers of corrugated board and automatic production line.

Parts List and Technology Specifications

Main Specification

Model: WJ150-2200 5Layer Corrugated Carton Production Line

- Design speed: 150m/min

- Normal work speed: 100-120m/min

- Manufacture width: 2200mm

- Note: The roll paper which is used to test the production speed should meet following requirements:*Grade: Min. B * Moisture content: 11% ± 1% *Face paper: 100~350g/m2 * Liner paper: 100~250g/m2 *Corrugated paper: 100- 200g/m2

- Flute profiles: A,B,C,E flute(as per clients request)

- Steam requirements:Steam quantity: 1600-1800Kg/Hr Max. pressure: 1.3Mpa

Normal pressure: 0.98-1.12MPa - Electricity: 120kw Voltage : 380V 50Hz three-phase, or four phase

- Equipment Direction:Left or Right transmission will be according to client`s requirements

Remarks: Buyer supply part:

- Air compressor and glue pipeline

- Main power, electric wire from operate box to main power.

- Water supply, pipeline and barrel.

- Water, electric and gas, main groundsill foundation.

- Test machine use Raw materials ( paper roll, corn starch, caustic soda, sodium borax) to test machinery

- Machine use oil, lubricate oil and high temperature lubricate oil.

- Installing engineer’s food, hotel and supply enough workers to help installing and test machine.

- Boiler 2T supply by customer and the pressure 1.25Mpa and the working pressure is 0.8~1.1

WJ150–2200 5Layer Corrugated Carton Production Line Price List

| Design speed 150m/min. work speed: 80-120m/min | |||

| No. | Machine name | Qty | Remarks |

| 1 | Mill roll stand | 3 | 1.Hydraulic drive, pneumatic disc brake. expand or tooth

2.Hydraulic valve made in Tianyuan . |

| 2 | Railing and track | 6 | 1.8m railing with pulley

2.16# channel steel |

| 3 | Pre-heater | 2 | 1.Dia 600mm, electric adjust wrapping angle

2.Wall Thickness 18 |

| 4 | Single facer | 1 | 1.Adsorption,Dia320mm

2.Corrugated Rolls Beijing with material 48CrMo high quality alloy steel 3.Digital show glue quantity.glue part can remove 4. Electric adjusts glue area. 5.6pcs shaft ,gimbal drive |

| 5 | Double layer bridge conveyor | 1 | 1.Adsorption, frequency leading paper

2.Double suction 3.200mm main beam channels, independent inverter motor drive pull paper feed, adsorption tension. Electric correction。 |

| 6 | double pre-heater

pre-heater |

1 | 1.Dia600mm, electric adjust wrapping angle

2.Wall Thickness 18 |

| 7 | Gluing machine | 1 | 1.Frequency control and figure show, PLC control

2.main bearing adopts imported product. 3.Diameter 280mm. 4.Press roller suit for high temperature |

| 8 | Double facer | 1 | 1.Hot plate:600mm×16pcs

2.Air cylinder correct cylinder belt error 3.4m cooling section 4.lift-down cotton belt |

| 9 | Main drive | 1 | 1.Diameter 600mm

2.Rubber roller 3.Independent reducer box. |

| 10 | slitter scorer | 1 | 1.5 blades 8 scorer

2.Electric adjust move 3.Precision:±1mm |

| 11 | NC cutoff | 1 | 1.Computer system Taiwan Tianlong.

2.Full AC servo control, energy storage brake, helical blade structure, helical gear transmission, oil-immersed gears pressure protective,10.4-inch touch screen display. |

| 12 | Sheet delivery | 1 | 1.Auto counter, single layers

2.Electric horizontal output 3.Servo drive platform lifting, three section of frequency transport,automatic points stack discharge, Imported high-strength belt output, out paper side standard transport aircraft. |

| 13 | Glue making system | 1 | 1.main pot 1 set, carrier pot 1 set, and storage pot 1set,

2.glue station pump, single facer glue pump and gluing machine glue pump. Total 7pumps 3.Circle supply glue, pipeline provided by customer |

| 14 | Pneumatic system | 1 | 1.Separator and 1 set air storage Jar and air pump.

2.Pipes provided by customer. |

| 15 | Electric system | 1 | 1. Adopt famous brand

2.including wires from switch board to main motor. |

| 16 | Steam system | 1 | 1.pipes above valves provided by customers. |

Production line machine Specification:

Hydraulic Mill Roll Stand ZJ-V6

Technical Parameter:

- Stand move mode: Full hydraulic action

- Working width: Max 2200mm Min1200mm

- Paper diameter: Max¢1500mm Min¢350mm

- Single Load: Max 4000kg

- Stand main bearing diameter: ¢242mm

- Air working pressure(MPa):0.6~0.9MPa

- Total power:3kw

- Working power:Pressure380V Frequency50Hz

- Dimension:3850×1600×1650(L×W×H)

Hydraulic system parameter

- Working pressure(MPa): 12~16 MPa

- Hydraulic pump working span(swing): ¢100mm×460mm

- Hydraulic pump diameter (clamption): ¢63mm×670mm

- Hydraulic station motor power:3kw Continuous work

- Hydraulic station electro magnetism working pressure:220V 50Hz

Characteristic

- Symmetry structure could install two bundles real paper at the same time, and change the paper without any stop.

- Adopt hydraulic drive that could make the real paper lift-lower, clamp and release and move.

- Adopt pneumatic strain to adjust the real paper.

- Expanding clips design.

- Tension control by pneumatic brake system, manual controlled and also can be controlled by splicer.

Raw materials and bought in parts:

- Stand main bearing adopt:High quality thick-walled seamless steel pipe. Origin: Chengdu

- Two side wall plates and arms adopt: HT250 casting Origin: Hebei

- Main beam like channel steel: 280mm Origin: An steel

- Bearing:made in Ha, Wa , Luo .

- Electrical device:made in Schneider .Chint.

- Pneumatic component: Airtac, Zaozhuang Origin: Taiwan, Shandong

- Hydraulic: Beiye Group(Huade) Origin: BeiJiing Zaozhuang, Shandong

Railing and pulley

Technical parameter

- The application of line width :1800mm

- Dimension:5000mm×400mm×300mm(L×W×H)

Characteristic

- Push the real paper to the right position, handiness and agility.

- Track buried and main frame welded by 14 channel steel, sturdy and durable

- The steel plates above the scene welded after the installation.

- Match two dollies to install the paper from two sides.

Raw materials and bought in parts

- The track and dolly materials:Tang steel, Ji Steel production profiles

- Bearing: Made in Ha, Wa, Luo.

SF-320S Single facer

A.Parameter :

- Machine width: max2200mm.

- Design Max speed: 150m/min

- Working pressure: 0.6-0.9Mpa, steam work pressure: 0.8-1.3Mpa

- Steam consumption: 0.65-1t/h Temperature requirements: 160-200℃

- Machine power: 15kw Working power: 380V, 50Hz

- Dimension: 3800mm*2400mm*2300mm

B.products characteristics :

- Cardboard transmitting method adopts wind absorption, and keep flute profiles stable under the running condition of high speed.

- The wind machine absorbs corrugated paper to corrugated rollers through vacuum box and form corrugated profile.

- The width of wind groove of lower roller is not exceeding 2.5mm,and will less fringe marks of single corrugated paperboard.

- Transmission part adopt gimbal transmission, away from vibration source, and make the transmission more steady and reliable, and easy to maintain.

- The speed reducing box is oil-lubricating, close gear transmission, and will reduce machine vibration.

- Glue unit adopts auto-supply glue circularly, pneumatically reset and has buffering effect.

- Glue area will be electrically adjusted, glue unit can be running independently when machine steppes, and prevent glue running out.

- Upper corrugated roller surface are treated by special mesh snicked and chrome plated.

- Glue unit independent drive, pump-draw style, easy maintain and clean.

- Upper-lower corrugated roller are made of high quality 48CrMo alloy steel, and after heat-treatment, the rigidity is HRC 55-62, the surface are grinded and plated chrome.

- Flute profiles: A flute height 4.7mm B flute height 2.75mm E flute height 3.75mm(the flute profiles can be made according to client`s requirements)

C.Parameter of main parts:

- Upper-lower corrugated roller are made of high quality 48CrMo alloy steel, and after heat-treatment, the rigidity is HRC 56-60, the surface are grinded and plated chrome.

- Upper corrugated roller: ¢280mm lower corrugated roller: ¢280mm Origin: Beijing

- Pressure roller:¢320mm, #45seamless steel pipe with quenching treatment

- Applicator glue roller: ¢242mm45# seamless seel pipe, from Chengdu

- surface are treated by special mesh snicked and chrome plated

- Doctor glue roller: ¢140mm, 20# seamless seel pipe, from Chengdu

- Pre-heating roller: ¢360mm 20Gsteel from Ji Steel Wall thickness:20mm

D.Raw materials and bought in standard parts:

- Wall plate two sides and seat: HT250 Origin : Hebei

- The seat materials of transmitting unit: welded with channel steel

- Rotary joints, metal soft tube: Lu guan qiu Shandong

- Bearings:(mainly)NSK Japan;

- Common bearing: Wa, Ha, Luo, bearing with seat: Jinrun,Zhejiang (Chinese best product)

- Engines: Main engine: 18kw 1set continues working

- Wind absorption machine: 7.5kw 1set continues working

- Glue unit self-running engine:0.75kw 1 set Chengbang, Taiwan Short time work

- Glue width-adjusting engine: 0.1kw 2sets Chengbang, made in Taiwan Short time work

- Electric appliances: Schneider .Chint Pneumatic parts: Airtac, Taiwan

Pre-heater MH-600

Technical Parameter

- Working width:2200mm

- Pre-heater Roll Diameter:¢600mm *Angle adjustment range:60~270 degree

- Steam temperature:150~200℃ *Steam consumption:0.25t/h

- Steam pressure:0.8~1.3MPa

- Working power:Electricity pressure380V Frequency50Hz

- Total power:0.55kw

- Dimension:4400mm×1200mm×900mm(L×W×H)

Characteristic

- The surface of the rolls are polished and plated with chrome.

- Electro motion adjust of the dimension of per-heater, and the range of adjustment:60-220 degree

- Per-heater rolls professional manufactured, consistent with national safety standards for pressure vessels.

- Pre-heater roller and paper guide roll are plated.

- Electro motion adjust of the dimension of per-heater,suit for different paper and speed.

Raw materials and bought in parts

- Both sides of panel material:HT250 casting Origin:Hebei

- Guide paper roller material: 20 # steel Origin:Bao steel

- Pre-heater roll material: 20Gsteel,Wall thickness 20mm Origin:Ji steel

- Main bearings:Made in Ha, Wa, Luo . with seat bearing made in Jinrun, Zhejiang.

- Steam rotary tie-in, Metal hose:made in Luguan, Shandong.

- Adjust motor: 0.25kw Decelerate rate1: made in Zhejiang

- Electricity device:Schneider. Chint.

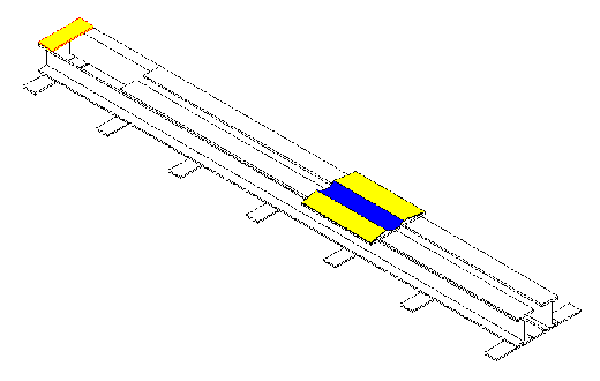

Heavy Bridge Conveyor BC-200

Parameter:

This is conveyor bridge is designed for transport single-side corrugated paper by the top of the single facer to the multiplex pre-heater.

products characteristics :

- Adopts suction tension device, use high pressure adsorption motor to suction the single face paper, make it flat to input the next process.

- Installing two operate board, could be adjust on the bridge and ground.

- Paper receiving device adopts independent frequency conversioncontrol, manufacture enough single face paper to wave type, and makesure enough storage of single face paper, to keep in-phase different speed in manufacture.

- With feeding paper frame on the bridgeand two conveyor belt to transport the single face paper to the bridge, forming wave type to storage the single face paper.

- The Automatic adjust the position of single face paper, reduce waste paper ratio of the manual operation.

- Equipped block part, in order to single face paper stack well on the bridge when the machine in high speed.

Raw materials and bought in parts

- Channel steel of main bridge:# 20 steel Origin: An Steel

- Paper-receiving unit transmitting belt: Nylon industry belt.

- Paper storage unit transmitting belt: Parallel transmitting belt

- Guiding paper engine( conversion control): 3.0 kw 1 set continuous work Origin Wuxi

- Absorption tension engine: 3.0 kw 1 set continuous work Origin Wuxi

- Paper width adjustment engine: 0.25 kw 2 sets short time work Origin: Hengshui

- Bearings: Wa, Ha, Luo bearing with seat :Jinrun, Zhejing.

- Electric appliances: Schneider. Chint.

MH-600T double Pre-heater

Technical Parameter

- Working width:2200mm

- Pre-heater Roll Diameter:¢600mm

- Angle adjustment range:60~220 degree

- Steam temperature:150~200℃

- Steam consumption:0.35~0.45t/h

- Steam pressure:0.8~1.3MPa

- Total power:1.1kw

- Electricity pressure:Electricity pressure380V Frequency50Hz

- Dimension:4000mm×1200mm×1800mm(L×W×H)

Characteristic

- Each roller surface is well whetted and chrome plated sooth and durable.

- Electro motion adjust the dimension of pre-heater, the range of adjustment: 60-220 °

- The pre-heating roller is made according to national container safety standard

- Pre-heating roller and guiding paper roller are eclectically galvanized

- Electro motion adjust the dimension of pre-heater, suitable with different grades of paper and machinery speed

Raw materials and bought in parts

- Both sides of panel material:HT250casting Origin:Hebei

- Guide paper roller material: 20 # steel Origin:Bao steel

- Pre-heating roller: 20G steel wall thickness: 20mm Origin: Ji Steel

- Main bearings: Wa, Ha, Luo, the bearing with seat is from Jinrun, Zhejiang

- Steam rotary tie-in:Johnson

- Metal soft pipe: Luguanqiu, Shandong

- Water valves: Beijing

- Adjustment engine:speed reducing ratio: 1:100 short time working, *Electrical appliances: Schneider Chint.

GM-280 Gluing Machine

A .Parameter:

- Working width: 2200mm

- Design work speed: 150mm/min

- Steam temperature pressure: 150~200℃ Steam working pressure:0.8~1.3MPa

- Steam consumption:0.1~0.15Mpa, Compress air: 0.6~0.9MPa

- Total machine power: 3kw

- Power: 380V, 50Hz

- Whole machine dimension(L×W×H):4000mm×1280mm×2100mm

- Pressing paper type: Pressing roller type

- Heating roller diameter: 360mm, thickness: 20mm, surface experienced grinding and chrome plating treatment.

- Leading paper roller diameter: 86mm, thickness: 12mm. surface experienced grinding and chrome plating treatment.

- Pasting roller diameter: 280mm, thickness: 25mm, surface experienced grinding and chrome plating treatment.

- Doctor roller diameter: 140mm, thickness: 15mm, surface experienced grinding and chrome plating treatment.

B . products characteristics :

- Independent engine transmitting, conversion control.

- Applicator roller surface are treated by mesh snicked and chrome plated.

- Doctor roller and presser roller are well whetted and plated chrome.

- Pressure paper unit of pressure roller is pneumatic, flexible and convenient to operate

- Auto-circulating supply glue, so as to prevent the glue deposited.

- Adopting pre-heating set, so as to avoid glue burnt.

- All raw materials of pre-heating roller, applicator roller, dividing glue roller is from Chengdu seamless steel pipe factory.

C .Raw material and bought-in parts :

- Wallplate two sides: steel 45#Origin: Hebei

- Bearings: from Ha, Wa, Luo(Chinese famous brand)

- Electrical appliances: Schneider.Chint

- Pneumatic parts: Airtac Origin Taiwan.

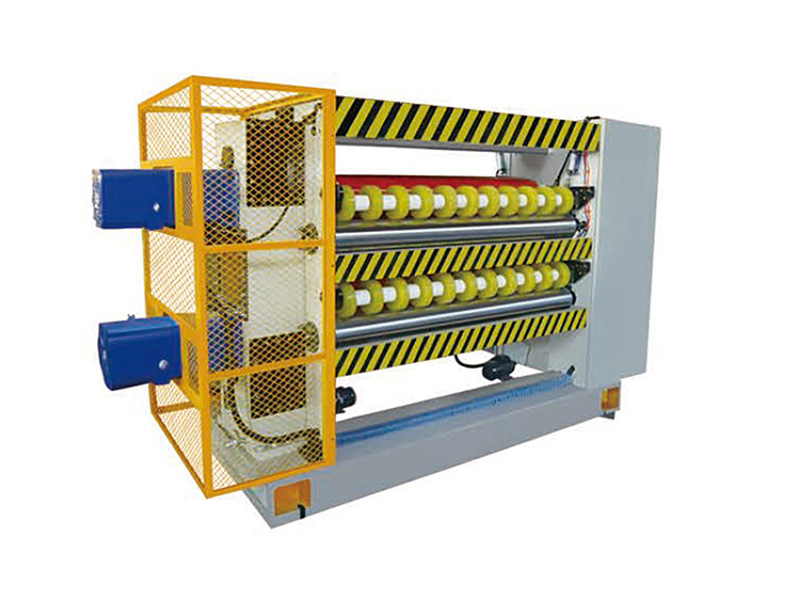

Double Facer DF-600

A .Parameter:

Double facer is corrugated paper enter into hot plants heating and molding after pasted glue, and become board after cooling.

Technical Parameter:

- Working width:2200mm

- Max. machinery speed:150m/min

- Temperature required:160~200℃ Steam pressure:0.8~1.3MPa

- Steam consumption:1.2~1.8t/h Compressed air pressure:0.6~0.9MPa

- Heating plate length:10800mm(600mm×18pcs) . cooling section length:5000mm

- Total power:55kw

- Electricity: 380V 50Hz

- Dimension: 18200mm×2000mm×2600 mm (Lx W x H)

Heating plate unit

- Dimension:2200mm×600mm×135mm.(L x W x H)

- Material: 20G steel, Ji Steel

- Process technique: surface is whetted

- Join method: single cross type,

- Temperature method: many groups controlled.

- Pressure method: adopting dense pressure roller style

- Pressure roller diameter:¢60mm solid 45# steel. Origin Shou Steel

- Supporting roller diameter: ¢60mm solid 45# steel Origin Shou Steel

Characteristics

- Whole body is high strength channel steel, stable, beautiful, suitable for high speed machinery running.

- Heating plate is made according to national container safety standard, of 600mm steel. Inside, S type construction will raise the steam usage efficiency. More welded rods will keep heating plate unchanged in shape.

- Heating section is tense pressure roller structure, cardboard sticks firmly and levels off.

- Steam pipes enter mouth, drainage mouth is S type, heating plate temperature is balanced and evenly.

- Heating plate’s temperature is different in different section, suitable to different machinery speed.

- Heating section pressure roller is hydraulic lifting whole body, stable, safety and reliable.

- The upper canvas strap is equipped electro motion or manual deflection adjusting set, one pneumatic strain set, one manual strain set. The lower canvas is equipped strain and left-right adjustment set.

- Drive unit adopts wearable, mesh rubber of big diameter, less belt skip, and raise stability when machinery running

- Independent speed reducing box, less noise, roller diameter¢600mm adopts seal oil lubricating gears.

Driving part:

- Main motor drive upper and lower driving rollers by cotton belt, makesthe carton to next process.

- Steel rollers covered with high qualitywear-resistant rubber with “V”stripe.

- The driving gear box adoptsoblique gear structure, high strength, low noise, and convenient for maintaining.

- Easy to inject lubricate oil for the gear box.

- Upper roller diameter Ø600MM

- Lower roller diameter Ø600MM

- Main power: 30kw, frequency motor with transducer.

SS-250P Thin blade slitter scorer

Technical Parameter

- Design speed:200m/min

- Max. slitting width:2200mm

- 6 blades 10scores *the whole machine can move left-right ±90mm

- Whole machine dimension:4050×1450×2380

- Total power:15kw

- Electricity:380V 50Hz

- Working pressure:0.6~0.9 MPa

- Comparative moisture:20%~90% *Temperature required:5~50℃

Characteristics

- Conversion adjustment speed can automatically follow production speed, and keep in-phase

- In the process of production, auto- grinding edge system can be still working while machine stops, and can set the interval meter and the grinding time at any time according to the material and condition of hem.

- 1mm high quality blade slits cardboard in high speed, slitting line is smooth, beautiful, unchanged shape, and good for printing.

Raw materials and bought-in parts

- Mail wall plate two sides: Q235A

- Cutting motor ( frequency control ): 7.5 kw 1 set continuous work

- Scorer motor: 3 kw 1 set continue work

- Horizontal movement motor: 0.75kw 1 set not continuous work

- Blade: Diameter 260mm Materials: rigid alloy steel

- Bears are from Wa, Ha, Luo cities

- Electric appliances: Schneider. Chint.

- Pneumatic cylinder, pneumatic parts: Tianyuan, Origin: Shandong

Characteristics:

- Special structure design, high tensile strength wall plate and seat, there are watching window on wall plate two sides, convenient and easy to maintain.

- Transmitting system adopts oil pump auto-cycling lubricating, make sure transmitting precision.

- Adopting high precision, high rigidity whetted gears, bearing high running and durable, make sure blade-edge joggle exactly, cardboard is level off and clean

- high precision shaft, blade carrier design, cutting stably when machine high speed running

- Special changing blade structure, quickly and easily changing blade

- The system is made according to C.E. standard, and has been strictly tested by industry computer. The quality, life, and stability can be guaranteed.

- Driving unit adopts A.C. Servo drive, quickly and exactly act

NC-S N.C rotary cutoff

Technical parameter

- Working width: 2200mm

- Max. cutting speed:150m/min

- Cutting cardboard:max. 9999mm min. 500mm

- Cutting precision:±1mm in stable speed

- Cardboard: original paper: <360g/ liner paper<200g/

- thickness3-14mm moisture content <10%

- min. width warping1000mm <30mm

- Comparative moisture content:20%~90% comparative temperature:5℃-50℃

- Steam pressure:0.6-0.9MPa

- Cutting cardboard blade shaft diameter:upper¢ 224 mm low¢ 228 mm

- Guiding cardboard shaft diameter: front upper ¢165mm(sun wheel) front lower¢135mm

- Back upper ¢135mm back lower¢135mm

- Electricity :voltage 380V frequency 50Hz current 80A

- Total power:32.5kw

- Dimension:4500mm×1600mm×1500mm(length x width x height)

Characteristics

- Special structure design, high tensile strength wall plate and seat, there are watching window on wall plate two sides, convenient and easy to maintain.

- Transmitting system adopts oil pump auto-cycling lubricating, make sure transmitting precision.

- Adopting high precision, high rigidity whetted gears, bearing high running and durable, make sure blade-edge joggle exactly, cardboard is level off and clean

- high precision shaft, blade carrier design, cutting stably when machine high speed running

- Special changing blade structure, quickly and easily changing blade

- The system is made according to C.E. standard, and has been strictly tested by industry computer. The quality, life, and stability can be guaranteed.

- Driving unit adopts A.C. Servo drive, quickly and exactly acts.

- Special electricity structure design, more saving electricity, can avoid the problems of not stable electricity.

- Adopts special power bring and storage type design, save electric and could overcome electric voltage not steady environment.

- System has self test function, can prevent machine loss because of abnormal usage and false operation

- Computer automatically adjusts cutting speed according to cardboard specifications and production speed, automatically follow cardboard running speed, assure in –phase.

- Computer reserves 999 groups of order, and auto-complete based on the program and preferential condition, the screen display various production message.

- Cutting length: 500~9999mm,cutting precision :±1mm。

- Rotary blade is made in Tainwan

- Shaft bearings are from NSK, Japan, suitable for machine high speed running, durable.

Raw materials and bought-in parts

- Wall plates two sides and seat:HT250 casting Origin: Hebei

- Upper lower shaft: 45# steel

- Blade:W18crv5Co5(high speed tool steel)

- Gear:40Cr whetted, quenched and tempered

- Main drive engine(AC. servo)power: 12.5kw, 1set Origin: China

- Transmitting cardboard engine power: 3.0kw Origin: China

- Oil pump engine power: 0.25kw Origin: China

- Computer control system

- Bearing: (main) NSK Japan (common) China

- Pneumatic parts: Yadeke Taiwan, Tianyuan Shandong.

CF-200T paper sheet delivery

A .Parameter:

Max length: 3000mm

Pneumatic pressure: 0.6–0.9MPa

Work voltage: 380V 50Hz

total machine power: 6kw

B . products characteristics :

1. Automatic store up and collect the carton sheets.

2. Electric horizontal output.

3. Vertical receive the carton sheets adopts wider conveyor belt to transport.

4. Carton sheets quantity and height was control by switch then push out.

C . Raw materials and bought in standard parts:

1. Belt transport motor: 3kw, 1set, non-stop working

2.Horizontal arrange carton sheets motor: 1.5 kw, 1set, non-stop working

3.Transport belt: industry belt 4. Main frame channel steel: 20# steel.