BFY-HZ 3000mm Corrugated Cardboard Thin Blade Slitter Scorer machine

Corrugated cardboard slitting scoring machine china supplier

- Intelligent corrugated board slitting and creasing machine

- All sizes can be input on the touch screen and adjusted automatically.

- One minute quick order change, suitable for small orders.

- High speed models, improve production capacity and reduce labor costs.

- The delivery period is 30 days and the warranty period is 48 months.

Share This Page

Function and characteristic:

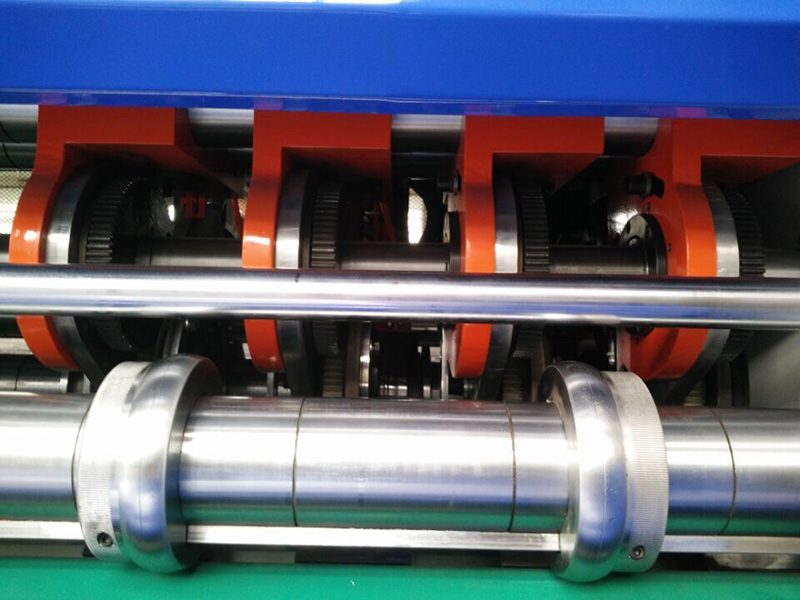

- The machine separating paper adopt thin knife technology, overcome appearance of raw edge and flatten ,from traditional thick corner knife, the products of paperboard will be no oppose corrugated, not to be bristled, tidy side, clean and no flatten appearance and good straight line, improve the outward appearance and quality of the paperboard.

- man-machine interface .PLC touch screen control. computer order management ,easy to operate. replace the order faster. can be stored orders in advance.

- Grinding knife include of man-power and automaticity, can do separating cut while sharpening knife, Not only keep sharp of the knife, but also provide the productiveness of working.

- Creasingfunction: creasing technology uses the French Martin technology to hard pressure soft. For high, middle and low board, creasing without tearing phenomenon.

- Feeding roller is seamless steel tube, parcel wear-resisting rubber, and do dynamic balance correction.

- The machine shaft, roller are adopted high quality steel, grinding processing, high precision computer dynamic balancing correction and surface hard chromium plating.

- The whole machine drive bearing, the main transmission parts all adopt the domestic well-known brand: “HRB”, the key part uses Japan “NSK” brand, the maintenance is simple, the service life is longer.

- The main motor is adopted frequency conversion control. It makes start, running more steadily and save more energy.

- Security guard network. thin blade slitter scorer on working .speed fast ,blade running also fast.

- the thin blade Drive way , adopt Synchronous belt(import),The noise is small and long life.

- Electrical components: adopt import brand .Siemens, Schneider. To ensure the machine more stable. To avoid unexpected circumstances thin blade for broken, and hurt the operator safety. Retainer also has to be automatic cut-off, automatic lighting function, for customers in the operation convenience.

- The front and rear sides of the machine are equipped with protective nets to ensure safer operation.

technical parameter:

| Model | BFY-HZ3000 |

| The configuration type | 4blade 6 scoring |

| Max feeding paperboard size(mm) | 3000mm |

| Max cutting paperboard size | 2900mm |

| Min cutting paperboard size | 150mm |

| Min slitting width | 120mm |

| Min feeding length | 450mm |

| Min scoring width | 40/135mm |

| Working speed(pcs/min) | 160m/min |

| Thin blade size | Ø200x122x1.2mm |

| grade of thin blade | High speed tungsten carbide |

| Machine drive | Electric/pneumatic |

| Scoring ,slitting ,seat movement | Plc touch screen electric adjustment |

| Feeding | manual |

| Layer of paperboard | 3 / 5 / 7 |

| Scoring high | 0-12mm |

| Slitting and scoring precision | ±0.5mm |

| Scoring distance | Manual adjust |

| Auto counting | yes |

| Main motor power | 11kw |

| Weight | About 3T |

| Overall dimension(mm) | 1500x4200x1500mm |

GET A FREE QUOTATION

Related Products