2Layer Cardboard Making Machine Steam Heating Single Facer Corrugated Machine

2Layer corrugated cardboard making machine china manufacturer

1.this line consists of three machines, single facer amchine ,mill roll stand and sheet cutting off machine .

2. Low price, economical and practical, high cost performance.

3. The maximum speed is 80m / min.

4. The heating mode is optional, including electric heating, steam and heat oil.

5. this line can make 2 layers of corrugated board. Add a manual pasting machine ,it can making 3/5/7layers corrugated cardboard .

Machine description:

The production line of this unit is composed of mill roll stand, single facer machine, paper cutter off machine and pasting machine. It can continuously produce and cut the required specifications of single-sided corrugated board. Drying is not necessary during production. Use with glue machine. It can produce corrugated board with more than 3 layers. It has the characterist of reasonable structure, advanced technology, good paperboard quality, high efficiency, less labor, simple operation and low price. It is an ideal equipment for producing corrugated boxes.

ZJ-V6 electric mill roll stand

Structural features:

parameters:

electric mill roll stand.

- Working width: max1400-2000mm

- Paper roll diameter: maximum ¢ minimum 1400mm ¢ 800mm

- Maximum load on one side: 2500kg

- Diameter of main shaft of rolling mill roll stand: ¢ 210mm

- Total power: 5.0kw

- Power of turnover motor: 1.5kwx1 sets; Cutting motor power: 0.. 37kwx4 sets

- Characteristics:

In two working positions, two reels can be clamped at the same time, and the reel can be loaded or unloaded without stopping production. The pickup cylinder adopts cast iron curve structure, which is light, firm and stable.

The symmetrical structure can install two bundles of real paper at the same time, and the paper can be changed continuously.

Using electric drive, the real paper tape can be lowered, clamped, loosened and moved.

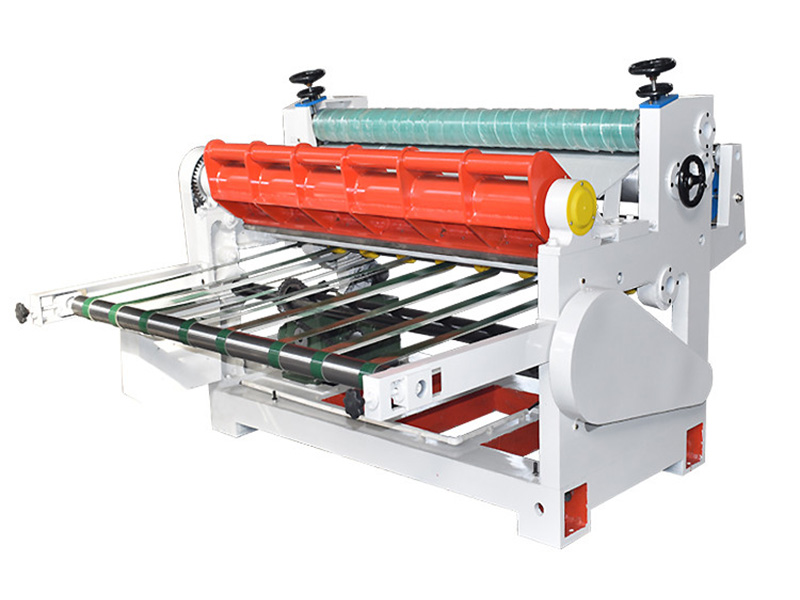

DW-280 fingerless type single facer machine

Structural features:

A.Parameter :

Machine width: max1600-2000mm.

Design Max speed: 80m/min

Heating type: electric / steam heating.

steam work pressure: 0.7Mpa Steam consumption: 0.5t/h

Temperature requirements: 140-160℃

Machine power: 15kw

B.products characteristics :

* Cardboard transmitting method adopts wind absorption, and keep flute profiles stable under the running condition of high speed.

* The wind machine absorbs corrugated paper to corrugated rollers through vacuum box and form corrugated profile.

* The width of wind groove of lower roller is not exceeding 2.5mm,and will less fringe marks of single corrugated paperboard.

* Transmission part adopt chain transmission, away from vibration source, and make the transmission more steady and reliable, and easy to maintain.

*The speed reducing box is oil-lubricating, close gear transmission, and will reduce machine vibration.

* Glue unit adopts auto-supply glue circularly, pneumatically reset and has buffering effect.

* Glue area will be electrically adjusted, glue unit can be running independently when machine steppes, and prevent glue running out.

* Upper corrugated roller surface are treated by special mesh snicked and chrome plated.

*Glue unit independent drive, pump-draw style, easy maintain and clean.

*Flute profiles:A flute height 4.7mm B flute height 2.75mm E flute height 3.75mm

(the flute profiles can be made according to client`s requirements)

C.Parameter of main parts:

- Upper-lower corrugated roller are made of high quality 48CrMo alloy steel, and after heat-treatment, the rigidity is HRC 56-60, the surface are grinded and plated chrome.

- Upper corrugated roller: ¢280mm lower corrugated roller: ¢280mm Origin: Beijing

- Pressure roller:¢324mm, #45seamless steel pipe with quenching treatment

- Applicator glue roller: ¢242mm45# seamless seel pipe, from Chengdu

- surface are treated by special mesh snicked and chrome plated

- Doctor glue roller: ¢120mm, 20# seamless seel pipe, from Chengdu

- Pre-heating roller: ¢400mm 20Gsteel from Ji Steel Wall thickness:200mm

HL-SD1600 Sheet cut off machine

Structural features:

- working width: 1400-2000

- Length range of cutting: 400-2400mm.

- The design working speed : 80m/min

- The single knife paper cutter is a device to realize the fixed length vertical and horizontal cutting of single-sided corrugated paper, and the use time of changing orders is short. Cutting has the characteristics of high precision and high speed

- The electrical components of this machine are imported Siemens Schneider brand

- The motor adopts variable frequency speed regulation and servo driver.

- The paper cutter is made of high-quality front steel, which is refined by forging, cold treatment and other processes, sharp and durable.

- The paper feeder is optional.

- Single corrugated paper collector is the supporting equipment of single blade paper cutter.

HL-BJ2200 sheet pasting machine

Structural features:

Sheet pasting machine

This machine is used to produce corrugated paperboard. The machine can mount the gum on the single and double sides of the corrugated paper, with the plank paper into the corrugated paperboard. The gum mounting roller of the machine has chosen the superior quality seamless steel pipe as its material and has the characteristics such as wear-resisting long operating life and so on.

The gum mounting machine is used to produce corrugated paperboard. The machine can mount the gum on single or double sides of the corrugated paper The gum mounting machine is used to produce corrugated paperboard. The machine can mount the gum on the single and double sides of the corrugated paper with the plank paper into the corrugated paperboard. The gum mounting roller of the machine has chosen the superior quality seamless steel pipe as its material and has the characteristics such as wear-resisting, long operating life and so on.

| Model number | Over the

paper width |

Over the

paper thickness |

Working speed | (mm)

Shape size |

| BJ-1600 | 1600mm | 18mm | 80m/min | 2200×400×1500 |

| BJ-1800 | 1800mm | 18mm | 80m/min | 2400×400×1500 |

| BJ-2000 | 2000mm | 18mm | 80m/min | 2600×400×1500 |

| BJ-2200 | 2200mm | 18mm | 80m/min | 2800×400×1500 |

| BJ-2500 | 2500mm | 18mm | 80m/min | 3100×400×1500 |