automatic carton boxes 2 color printing slotting and die cutting machine

Vacuum adsorption Automatic carton 3 colors Printing Die-cutting Machine with stacker

1. Vacuum absorption transfer paperboard, with high and stable transmission accuracy.

2. Customize the machine model and size according to customer needs.

3. Full automatic high intelligent high-speed printing machine. Quick order change.

4. Powerful factory, professional carton printing machine manufacturer.

5. The delivery date is 60 days.

automatic box 2 color printer slotter machine China manufacturer

Machine function and characteristic:

- The automatic carton boxes printing machineis in strict accordance with the European Union CE.

- Adopt vacuum adsorption transfer paperboard ( feeder paper the roller the surface is ceramic ,increasing wear life),Row wheel of dislocation arrangement roller, strengthens the cardboard transmission stability, need not to use paper wheel can smoothly through the cardboard printing department.

- The whole wallboard and important parts are ground by high-precision machining center and CNC grinding machine.

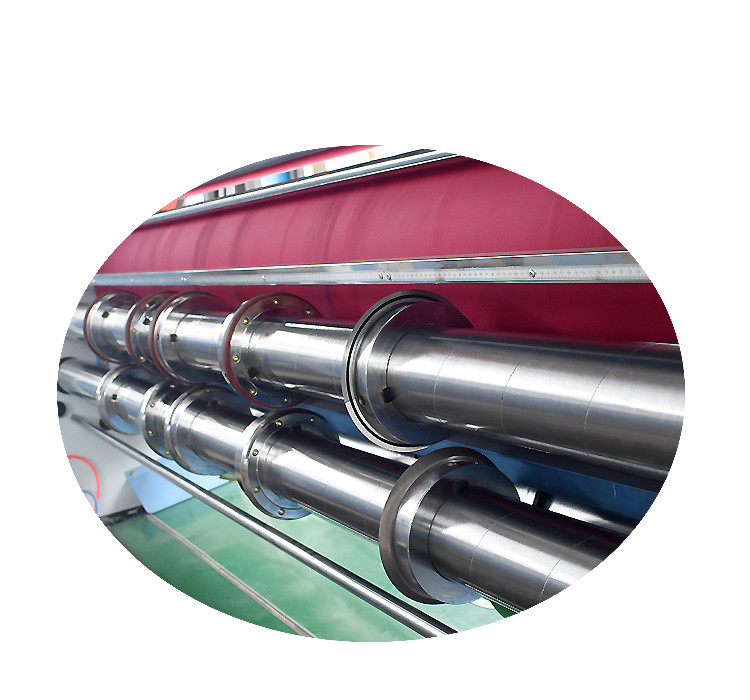

- The machine tool shaft and roll are made of high-quality steel, grinded, high-precision computer dynamic balance correction, and the surface is plated with hard chromium.

- The transmission parts (shaft and gear joint) of the printing machine are connected with free keys (LOCK-ALX) to eliminate the gap. It is applicable to high-speed operation with high torque for a long time. Improve machine life and stability.

- The transmission bearings and important transmission parts of the machine are made of international famous brands NSK and RMB, with a long service life.

- The engine lubrication system adopts automatic spray lubrication and is equipped with automatic liquid level balance system. Confirm that the oil level of each unit is the same.

- Intelligent machine, memory automatic reset, reduce the time for changing orders and save labor.

- The working clearance of the machine is adjusted with PLC electrical or touch screen, which is fast, accurate and convenient.

- Quick replacement function of rubber roll and anilox roll: when replacing rubber roll and anilox roll. The replacement only takes half an hour, which greatly saves the operation time and does not require professional technicians. Tradition takes at least one day.

- The whole machine adopts double frequency conversion control, which makes the starting more stable and energy saving. The phase adjustment is controlled by the frequency converter, and the shutdown time and operation can be adjusted (PLC touch screen operation).

- The machine has the function of storing common orders, which can store more than 999 orders, quickly change orders, and is simple to operate. Greatly improve work efficiency.

Main technical parameter:

| Design speed | 300(piece/min) |

| Economic speed | 180-220(piece/min) |

| Inside wallboard width | 2600mm |

| Max. Paperboard size | 2400*1200mm |

| Min. Paperboard size | 400x600mm

|

| Max. Printing size | 2300*1200mm |

| Max. Skip paper feeding size | 2400*1400mm |

| Max. Die cutting size | 2400*1200mm |

| Standard formed thickness | Hang plate7.2mm |

| Tinted precision | ±0. 5mm |

| Die cutting precision | ±1mm |

| Main motor power | 18kw |

| Fan motor power | 7.5kwx4pcs=30kw |

| Production power | 48kw |

| Total power | 55kw |

| Weight approximately

|

22 tons |

| Overall dimensions | 5000*4700*2200mm |

Auto feeder department:

1. The machine clutch:

1)The machine clutch electric control with alarm, moving last warning bell ring,

Ensure workers safety.

2)Pneumatic interlocking device, Locking is firm, convenient and accurate.

3)The main motor adopts frequency conversion motor, frequency conversion controller, energy saving, stable starting,

attached to the motor start protection device.

4) main engine self-locking function: the unit didn’t completely locking state, the main engine cannot be started, ensure the safety of the operator and machine; Host under normal working condition, the on-off function is automatically locked, avoid the wrong operation of the machine and personnel injury.

- Lead Feeder paper system

1)Using Germany Rexroth servo motor gently pressure on the leading edge paper-feeding mechanism, Has the response speed, high precision, good stability, The service life is long, etc the domestic advanced technology, its characteristic protection cardboard original strength, avoid collapse and thinning. Conducive to the smooth line pressing board after input, the system is stable, paper accurate, fast and suitable for all kinds of corrugated board

- The suction assist feeder paper ,11 kw high pressure centrifugal fan, Accordingto the cardboard bending degree of frequency conversion control air pressure ,to ensure warping board, thin board high-speed transmission.

- Dust removal device

1) Paper brush dust removal device, and is equipped with strong negative pressure suction fan, can remove the board by a lot of dust on the surface of the printing, paper scraps, etc sundry, improve the quality of printing.

- Feeder paper roller ( double roller feeder paper)

- Outer diameter: ɸ155 mm, up roller

2)45 # seamless steel tube, parcel wear-resisting rubber, and do dynamic balance correction.

- Feeder Paper roller gap dial electrical adjustment( Touch screen PLC control), adjustment range 0-12 mm .

4 ) The former feeder paper rubber roller (elastic rubber roller) for dynamic lift and fall , Automatically adjust the pressure, can reduce the strength fracture of the corrugated board.

5.Pat to orderliness device

The machine have pneumatic Pat to orderliness device, Cardboard transverse positioning more accurate, avoid waste.(computer control Pat to orderliness time).

Printing department(3color unit)

1、Printing roller:

1)The outer diameter :390.6mm, (including the plate of the outer

diameter is: ɸ 405mm).

2)The steel tube surface grinding , hard chrome plating. Roll horizontal direction and circumferential direction have its

benchmark scribed line, convenient to Installation the printing plate

3)Computer dynamic balancing correction, eliminate the internal stress, grinding machining, hard chromium plating, smooth operation.

4)Ratchet fixed volume edition axis. the printing roller have the correction function, adjust the plate convenient and quick.

5)Full Plate Hanging plate slot, suitable for 10mm×3mmplate of the article

6)Loading and unloading of the print plate , pedal switch of electric control forward and reversing.

About printing roller horizontally move by electric adjustment, the maximum amount of move for about 10 mm, with

a limit switch (PLC touch screen control)

7) Adopt vacuum adsorption transfer paperboard ( feeder paper the roller the surface is ceramic ,increasing wear life),Row wheel of dislocation arrangement roller, strengthens the cardboard transmission stability, need not to use paper ring can smoothly through the cardboard printing department.

8) Hanging plate system: with fine adjustment function, operation is more simple and convenient. Save printing plate operation time.

3,ceramic anilox roller:

1)Outside diameter is :ɸ215 mm.

steel tube surface coating ceramic grinding, laser engraving anilox .

- The Anilox mesh number : mesh No of unit 1 is 250. mesh No of unit 1 is 300. mesh No of unit 1 is 350.

- Than steel anilox roll printing meticulously, wear-resisting, long service life.

5)90-130 line printing can be realized

4、Phase adjustment mechanism:

1)Planetary gear structure.

2)Printing phase electric digital 360 degrees adjustment (motion and stop all can be adjusted).

3).Frequency conversion motor drive, according to the requirements change version of roller circumferential rotation speed, accurate to 0.1 mm, fast and convenient, printing roller to transverse PLC touch screen and electric digital adjustment, adjustment range, a total of 10 mm,

4). Intelligent printing roller is reset, fit self-return after locking ( every time separate ,then combine, printing roller will reback to the original location )

5、Ink circulation

1)Pneumatic diaphragm pump, ink stability, convenient operation and maintenance

- Ink filter, filtering impurities.

- Circulating pneumatic up inking.

- There is lack of ink alarm device, the real-time monitoring for the ink system working state, avoidno ink work.

6、Rubble roller:

1) outer diameter: Ø205mm.

2) steel pipe surface parcel wear-resisting rubble, and do correction balance.

3) rubble roller middle high is the special grinding, ink transfer effect is good.

4) rubble hardness: Ø60-65 degrees.,

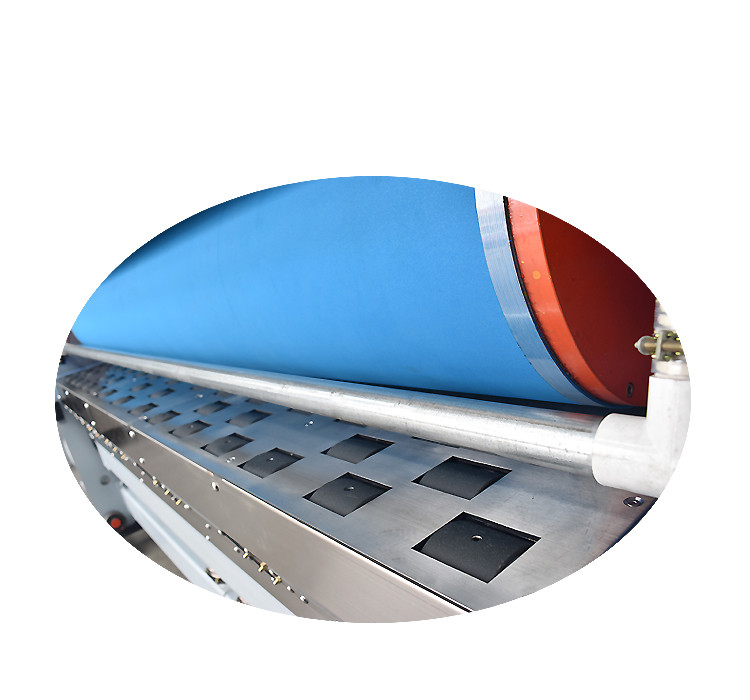

die cutting unit

1.The die cutter roller (down roller)

1)Outer diameter is: ɸ360mm . (not including die cutting mould )

- Centrifugal casting steel cylinder, the computer dynamic balancing correction, surface grinding, hard chromium plating, and increase the running stability.

- Die cutter mould fixed screw holes spacing of 100 * 100 mm

4)Apply to die cutting mould height 25.4 mm

- Die cutting thickness is :16 to 18 mm (three layer board), 13-15 mm

(five layer board).

2、 rubber roller (up roller)

1)The outer wall is: ɸ388mm

2)Cast steel material, surface grinding, hard chromium plating.

3)Balance correction, increase the running stability.

4)Electric digital and PLC touch screen and cutting die roll gap adjustment.

5)Rubber gasket thickness 10 mm, ( outside diameter is: ɸ404mm ), width is 250 mm.

3.Lateral (horizontal)movement, repair device:

1)Mechanical type horizontal 40 mm, move device, die-cutting equalizer automatic compensation linear

speed ,can make the die cutting rubber gasket uniform wear, prolong service life.

2)Repair adopt electric repair device, improve the rubber gasket repeat utilization rate, can repair 3-4 times.

3)Die cutting roller automatic pneumatic separation device, reduce wear rubber gasket , thus improve the

service life.

4,die cutting unit add slotting function .it is new patent technology .means this unit can make special shape carton box and normally carton box .

5.the die cutting rubber import from German famous brand .easy installation and transfer. the edge of the die cutting knife is smooth. The service life is long .it can reach about 12 million times. greatly reduce the cost of production.

6.Stripping belt longitudinal output, convenient cleaning waste paper.

7.Line-pressing system:

pressing wheel on the use of high-strength rubber wheel, large diameter, and other advantages, line-pressing perfect molding will not be damaged. Moreover, it is only 10 minutes to replace it with quick changing wheel mode, which is easy and convenient.

stacking unit

- The height of stack is 1600mm.

- Therise and descending of the machine tool platform is driven by the powerful chain, the rise and descending motor has equipped the brake function, so the machine tool can keep the fixed position to prevent failing down.

- With the paperboard pilling to the higher lever, the machine tool platform automatically adjusts the tilling height. The organization or lift the paper by pneumatic motion, the paper receiving tray will automatically open and catch the paperboard while the paperboards are piled to the planned height.

- Setting the save protect device, which was force the platform can not failing down abruptly, can make the worker safety.

- The surface corrugated belt can prevent the sliding of the paperboard.