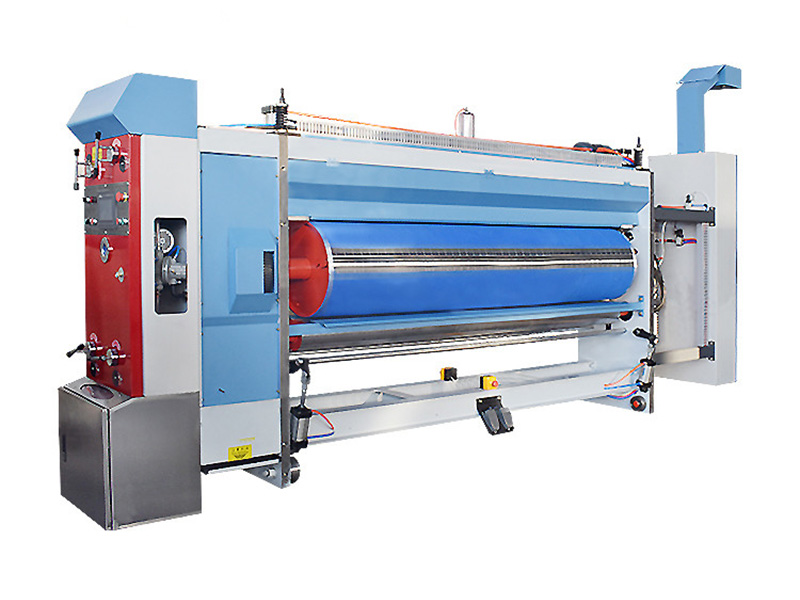

Automatic High Speed Flexo 2 Colors Printing Die Cutting Machine

Automatic flexo printing die cutting machine china manufacturer

1.carton machinery Source manufacturer, guaranteed after-sales service.

2.Competitive price, factory price, no link of trading company.

3.14 years of production Packaging machinery experience.

4.Perfect quality management system.

5.CE quality certification.

Share This Page

Function and characteristic:

- The automatic flexo printing die cutting machineadopted international famous brand appliances and computer software

- The engine drive gear is adopted 20CrMnTi alloy steel。

- The machine drive bearing ,important driving parts adopt Heavy-duty self-aligning bearing ,simple maintenance,long service life. (three big domestic famous brand:Hava los)

- The carton flexo printing die cutting machine of engine lubrication system is adopted automatic spray type lubrication,

- The carton box printing machine is adopted adjustment preset functions, feeding , printing, slotting, die-cutting, automatic zero resetting ,Separate and combine memory automatic reset.

- The main motor is adopted frequency conversion control.

- Optional: ceramic anilox roller, doctor blade and set ink system, stacking machine.

The carton printing Machine technique parameter:

| Model | 2800×1400 |

|

Color group |

to be configured according to user’s needs |

|

Printing paper |

A,B,C,A/B,B/C and A/B/C type corrugated paperboard

(the maximum interval 11mm) |

|

Width of machine inside |

2800mm |

|

Max.paper size |

1400 ×2600mm |

|

Max.printing size |

1400 ×2400mm |

|

Skip feeding paper |

1600 ×2600mm |

|

Printing plate thickness |

7.2mm |

|

Design speed(piece/min) |

200pcs/min |

|

Economic speed(piece/min) |

80-160pcs/min |

| Tinted precision | ±0.5mm |

| Die cutting precision | ±1mm |

| positive knife

Min. Slot distance negative knife |

170×170×170×170mm

260×90×269×90mm |

| Max.die-cutting size | 1400×2500mm |

| Printing plate diameter

(contain plate thickness) |

ɸ480mm |

Feeding unit of automatic carton flexo printing machine

- Automatic paper feeding, accurate and fast paper feeding, suitable for all kinds of corrugated board.

- Air suction assisted paper feeding, variable frequency control of air pressure according to the bending degree of paperboard.

- The paper lifting and dropping are driven by air cylinder, with fast and powerful action.

- The side baffle is adjusted by electric and computer touch screen, the front baffle is adjusted manually and synchronously, and the rear baffle box is adjusted by electric.

- Taiwan Super resistant leading edge paper feeding wheel, durable and wear-resistant.

- Alternate paper feeding device, continuous or alternate paper feeding can be selected as required.

Printing unit of box flexo printing die cutting machine

- Automatic ink leveling system

- Printing phase electric adjustment and PLC computer display adjustment (both operation and stop can be adjusted).

- Pneumatic diaphragm pump, stable ink supply, convenient and fast operation and maintenance.

- Ink shortage alarm device (when the ink amount is lower than the limit, the machine will alarm to avoid ink-free production)

- The printing phase fixing device adopts cylinder brake device.|

- adopts two stage turbine box to adjust the clearance of transfer roller

Die cutting unit of corrugated box printing die cutting machine

- The rubber pad roller adopts German brand.

- The die-cutting roller is attached with 4 slotted rings.

- Die cutting roller phase and axial adjustment, PLC touch screen control and electric digital 360 ° adjustment, and PLC touch screen and electric digital adjustment are adopted for axial and transverse.

- Rubber roller cutting repair mechanism and rubber gasket can be reused.

- The differential compensation device automatically adjusts the number of revolutions of the rubber cushion roller to make the shape of the die-cutting carton consistent with the knife die.

- The rubber cushion roller is mechanically set at ± 40mm horizontally to improve the service life of die-cutting rubber cushion.

Stacking unit of corrugated cardboard flexo die cutting machine

- The paper receiving arm can be operated manually or automatically, with safety mechanism and safety device.

- The lifting of the bed table is driven by a strong chain.

- The stacking height is 1600mm.

- The bed table automatically adjusts the tilt with the stacking height of paperboard, high speed, lifting motor, with braking function.

- Pneumatic paper lifting mechanism.

- Flat wrinkled belt to prevent cardboard from sliding.

GET A FREE QUOTATION

Related Products