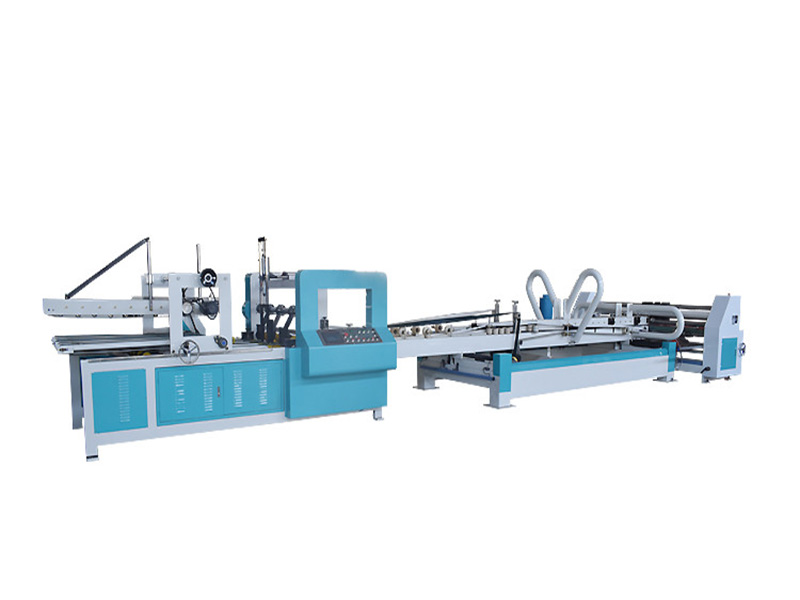

Fluer Machinery Automatic Corrugated Carton Folding Gluing Machine

Automatic corrugated carton folding gluing machine china factory

- The automatic high-speed carrton box folder gluer model is suitable for the 3/5/7layer of conventional caton boxes.

- Intelligent model, full computer operation. It can store 1000 order data. Equipped with PLC touch screen, the operation is simple and reliable.

- Automatic high speed model gluer machine ,auto cardboard feeding, the speed is150 pcs / min, increased production capacity and save manpower.

- Change orders quickly within 5 minutes. It has the function of secondary correction and perfect adhesion.

- After sales service guarantee, with a warranty of 48 months.

Share This Page

Main feature :

- Average gluing speed should be 8000-10000pcs per min, which improves productivity greatly.

- Two workers should assist to deal with whole producing line. Paperboard feeding, gluing, folding, adjusting, acounting can be done automatically.

- Adopted leather belt delivery feeding with airdraft.

- All convery belts were tooth nailed for accuracy. It equipped re-pressing function so that even more accurate whenfolding.

- Automatic re-adjusting if happen paper skew. Lowerdefective rate.

- Improving folding accuracy if happen paper skew through differential adjusting function. Scissors shapetail could nothappen.

- Automatic accounting, shape adjusting then stacking. All carton can be piled up according to a cartain quanlity.

- Can match with automatic strapping machine.

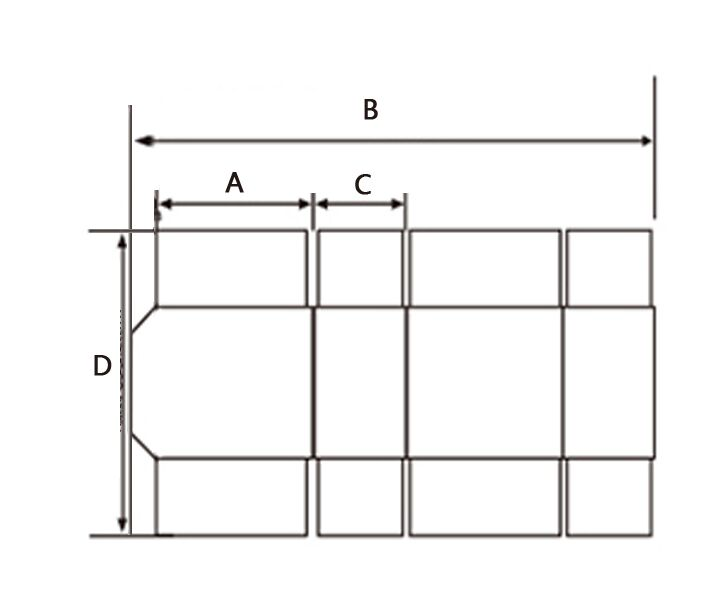

| Model | 2400 | 2600 | 2800 |

| Max cardboard | 900*2200mm | 1200*2400mm | 1200x2600mm |

| Min cardboard | 300*800mm | 300*800mm | 300x800mm |

| Size A | 80-880 | 80-880 | 80-880 |

| Size B | 800-2200 | 800-2400 | 800-2600 |

| Size C | 160-840 | 160-840 | 160-840 |

| Size D | 300-900 | 300-1200 | 300-1200 |

| Design speed | 120-200 piece/min | 120-200 piece/min | 120-200 piece/min |

| Overall dimensions | 12000*3100*1750 | 12000*3300*1750 | 12000*3300*2250 |

| Install area | 3500x14000mm | 4000x15000mm | 4200x15500mm |

| Power | 10KW | 11KW | 12KW |

| Weight | 6t | 6.5t | 7t |

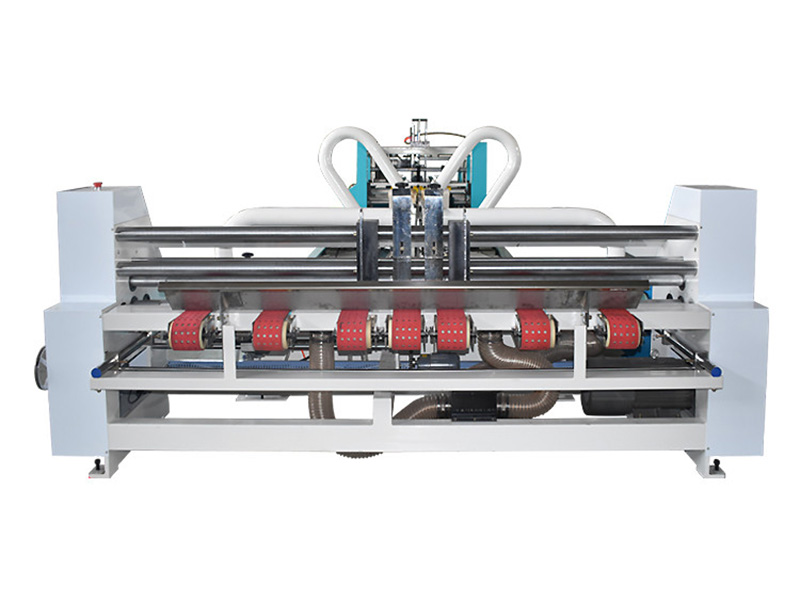

Feeding paper section:

- Vacuum suction feeding to feed warping paperboard easily .

- Quality electromagnetic clutch and brake adopted, feeding section controlled independent, operation easily

- Scorer wheel adjustable, suit for 2-8mm thick paperboard

- Second creasing structure can impress again the paperboard which was not creased well .

Gluing and Folding section

- Simpless structure and high reliability, glue quantity adjustable, cleaning easily

- Stainless steel glue wheel adopted, long life and saving glue cost

- Imported quality rubber belt adopted, automatic folding

- With paperboard rectify device and creasing rectify device

Rectification Department:

- Pressure connect between main machine and transmission, collect the box orderly and guide the box to conveyor device.

- Automatic re-adjusting if happen paper skew .lower defective rate.

- Improving folding accuracy if happen paper skew through differential adjusting function, scissors shapetail could not happen.

Counter and Stacker section:

- Stacking and counting are simple and reliable

- Digital control, operation easily and reliable. No-stop put in data and automatic counting

- With rectification function.

- Counting and put out by pneumatic, stable and quickly.

GET A FREE QUOTATION

Related Products