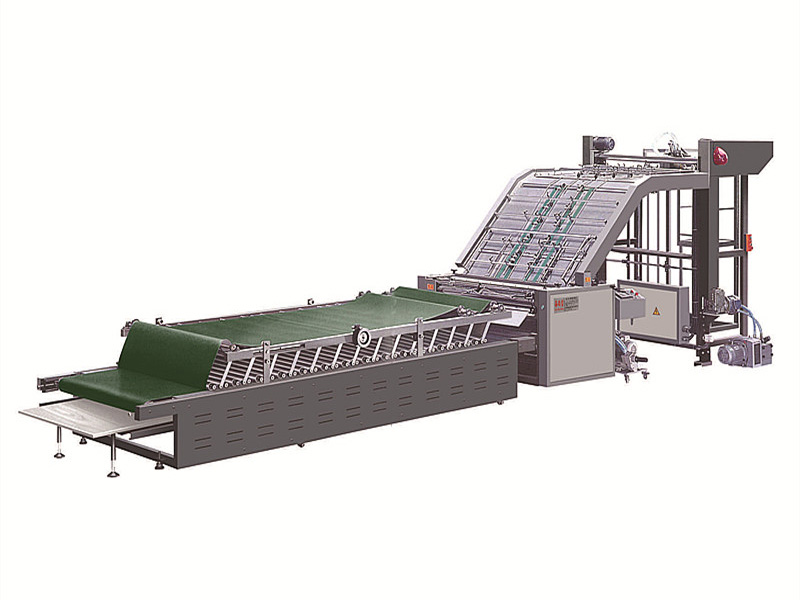

Fully Automatic Flute Laminator Machine For Corrugated Cardboard

Corrugated box flute laminating machine china factory

Share This Page

HL-TMJ-A 1400 type full automatic

Machine specification:

- The vacuum suction tray type Feida paper feeding system can accurately feed the paper into the machine; the circulating paper stacking rack can stack the next batch of surfaces without stopping the machine Paper, make it more efficient.

- The bottom paper adopts suction automatic feeding, which can automatically and synchronously track according to the speed of manual feeding.

- New concept elastic front gauge positioning, high positioning accuracy, bottom paper never ahead of time.

- The whole machine adopts touch screen / PLC / servo motor control system, the circuit system runs stably, and can display fault report automatically Police.

- Fully automatic glue replenishing system, automatically replenishing lost glue quantity, and cooperating with glue recycling to avoid glue loss and waste.

- The linear speed of the metering roller is designed scientifically to ensure the uniform glue quantity and avoid glue rejection during high-speed operation.

- Single side adjustment of pressure roller, convenient and fast.

- The rocker controls the rise and fall of the water washing stick, which is convenient for cleaning the lower roll of the upper rubber roll and convenient and fast for cleaning.

- Humanized design counter, convenient to record your daily workload. Easy to work by piece.

- One set of small press is selected. The length is 2.5m, and the length of large press is 5m.

Division introduction:

1.Feida system:

High precision and high-speed paper feeding, smooth paper feeding.

Reinforced paper feeding device, the angle of suction nozzle can be adjusted freely, suitable for different types of face paper

2. Pressure regulating system:

Single side pressure adjustment ensures that the pressure on both sides is consistent with that on the pressure scale. It is easy and convenient to adjust when changing paper specifications

3. Pressure transmission system:

Floating flattening design, no need to adjust the press pressure heightening design, conducive to the smooth operation of thick corrugated board

4. Electrical system:

Main electrical components adopt imported brand PLC tracking technology, automatic fault detection

Technical Parameters

| model | MJ-1300 | MJ-1500 | MJ-1600 |

| Max. Covering size | 1300×1250mm | 1500×1250mm | 1600×1250mm |

| Min. Covering size | 400×400mm | 400×400mm | 400×400mm |

| Machinery highest speed | 100pcs/min | 100pcs/min | 100pcs/min |

| Electric machine power | 10kw | 12kw | 12kw |

| Area /machine | 10×2 x2.4m | 10×2.2 x2.4m | 10×2.3 x2.4m |

| Precision | ±1.5mm | ±1.5mm | ±1.5mm |

| Cardboard THK | 3/4/5layer less 12mm | 3/4/5layer less 12mm | 3/4/5layer less 12mm. |

| Face paper | 150-600g | 150-600g | 150-600g |

| Weight | 4.8T | 5.2T | 5.4T |

GET A FREE QUOTATION

Related Products