Paperboard Making Machine 2 3 5 7Layer Corrugated Paperboard Production Line

Corrugated paperboard production line China factory

- Our company specializes in corrugated board production line. Professional technical team.

- Various models and configurations are available according to customer needs.

- The production speed ranges from 60-250 M / min.Width rangs 1200-2500mm.

- According to the needs of customers, different types of corrugated can be customized.

- The price is from economical to intelligent, which can be selected by customers according to the capacity requirements.

Share This Page

WJ100–2200 Type 7 LAYER CORRUGATOR LINE

| Type

|

Name

|

Qty.

|

Feature

|

| HB-I | Hydraulic Mill Roll Stand

( with trolly and track)

|

7 | Main shaft diameter is 242mm,doublecurve heavy rocker arm, tooth clip,mulitpoint brake,hydraulic lift,left and right translation.

Guide rail length is 6000 mm, the car uses 10 mm plate welding

|

| 320CR | Single Facer

|

3 | Corrugated diameter is 320mm, 48CrMo high quality alloy steel; Adopt independent gearbox, universal joint drive structure; Airbag ballast structure, PLC automatic control glue; Steam heating

|

| SP-1-600 | Pre-heater

|

6 | The roller ¢600 mm, including the pressure vessel certificate; electric adjustment angle; angle can be adjusted within the range of 360 °

|

| SP-4-600 | Quadruple Pre-heater

|

1 | The roller ¢600 mm, including the pressure vessel certificate; electric adjustment angle; angle can be adjusted within the range of 360 °

|

| OHB | Triplex Conveying Bridge

|

1 | Main girer is 200mm box iron,independent frequency conversion motor drive paper transport, adsorption tension. Electric correction.

|

| CGM-F | Triplex Gluer

|

1 | Glue roller dia. 269mm,carved 25 line pit type checker; each layer independent variable frequency motor drive

|

| HPM | Double Facer

|

1 | Hot plate 600 mm * 16pcs; press rollers lift by pneumatic,compressed press rollers structure

|

| FTKM | Thin Blade machine

|

1 | Electric blade, 5 blade 8 line, adopt tungsten carbide knive

|

| NC-120 | NC Cut-Off

|

1 | Full AC servo control, braking is energy storage type, spiral cutter structure, oil-immersed gear transmission, a 10.4 -inch touch screen display.

|

| SMA | Sheet delivery machine

|

1 | Electrical adjust the size of cardboard, cardboard transverse output controlled by pneumatic |

| ZQ | Internal Steam System

|

1 | Steam system components adopt GB valva; Contains rotary joint, up and down distributor , drain valve,steam trap and pressure gauge, etc.; Boiler and piping supply by customer

|

| ZJZ | Glue Making System

|

1 | Customer-owned pipeline。

|

MAIN SPECIFICATION

MODEL: WJ100-2200-7 LAYER CORRUGATOR LINE

- Manufacture width: 2200mm

- Design speed: 100m/minWorking speed:80m/min

- Note: The roll paper which is used to test the production speed should meet following requirements: *Grade: Min. B * Moisture content: 11% ± 2% *Face paper: 100~250g/m2 * Liner paper: 100~150g/m2 * Corrugated paper: 100- 200g/m2

- Flute profiles: A,B,C ,E flute(as per clients request)

- Steam requirements

Steam consumption:2500kg/h Air compressor pressure:0.8~1.1Mpa - Electricity: 380V, 50Hz,three-phase four wire type

- Equipment Direction:Left or Right transmission will be according to client’s requirements.

- Factory request size:specific length as to the foundation of drawing

HB-I Hydraulic Mill Roll Stand

Structure and Features:

- Reel paper lift-lower, clamp, loosen, movement, contra position operated by hydraulic.feeding kraft / reel paper quickly.

- Brake: multiple-pointbrake.

- Each stand with two feeding trolly

Spec of stand:

- Width: Max: 2200mm Min: 1100mm

- Diameter: Max: Φ1500mm

- Main Shaft Dia.:Φ242mm

- Max Weight:3000Kg(One side)

- Pneumatic Source Pressure(Mpa): 0.4—0.8Mpa

Spec of Hydraulic:

- Working Pressure(mpa):16-18mpa

- lift hydraulic cylinder:Φ100×440mm

- Clamping hydraulic cylinder: Φ63×1300mm

- Power Motor for Hydraulic Station:3KW –380V — 50Hz

- Magnetic Valve Voltage:380V 50HZ

Kraft paper feeding ground rack & trolly

Structure and Features:

- To feed the kraft paper to reel stand.

- The whole body of rack is under the ground, main frame: Model 14 channel steelwith ¢ 20mm drawing bar weld together,overall length 6000mm.

- Two racks for one reel stand to feed the kraft paper at both side.

SP-φ600 Preheter

Structure and Features:

- The pre-heater roller is under the stander of the 1stclass(grade) pressure vessel of the national.

- All the surfaces of every rollers have been grinded with high accuracy and chromed plated to less the resistance of paper preheating, long service of using life.

- Electric to enlarge the preheating area, preheating area can be in 360° to adjust the preheatinga

Common Spec:

- Working Width: 1800mm

- Diameter of the Preheater cylinder:Φ600mm

Preheating adjusting area by electric: 360° - Diameter of the roller for Preheating adjusting area by electric:Φ85mm

- Steam temperature: 150-200℃ Steam pressure: 0.8-1.3Mpa

- Power:250W 380V 50Hz Short Time(S2) Working Type

320CR Fingerless Single Facer

Glue Rollers:

| Diameter

|

Φ240mm

|

| Processing Way

|

Surface of glue roller is grinded, then with 25 line rut type net dot,then plating chrome

Surface of glue banlance roller is grinded then plating chrome

|

| Control Way

|

Airbag control of the Lifting Up-down

|

| Glue Supply

|

Glue circulating system(storage tank+glue pump)

|

Corrugated Rollers:

| Diameter

|

Down Roller:Φ320mm

|

| Material

|

48CrMo high quality alloy steel, rigidity HRC55°-58°

|

| Processing Way

|

The surface of upper-lower roller is plating chrome, annealing, hardening and tempering, surface grinded

|

| Fulte Type

|

(U/V) A\B\C\E

|

| Heating way of the reel paper

|

Steam heating

|

Press Rollers:

| Diameter

|

Φ324mm

|

| Material

|

medium steel (MS)45#

|

| Processing Way

|

The surface is grinded then plating chrome, hardening and tempering(With Buffer)

|

| Control Way

|

Airbag control of the Lifting Up-down

|

Preheater Rollers:

| Diameter

|

UP Roller:Φ402mm

|

| Material

|

seamless steel tube

|

| Material band or origin

|

Tianjin Iron & Steel

|

| All connected by flexible metallic tubes

|

|

Common Spec:

| Style of Transmit cardboard

|

Vacuum Cover adsorbable style, Hight pressure Draw fan.with wind control Adjusting & noise deadening device.

|

| Style of Control Roller

|

Pneumatic control the upper roller, pressure roller and glue roller

|

| Driving Way:With frequency inverter

|

|

Common Spec:

- Working width: 2200mm

- Design Speed:150m/min WorkingSpeed: 120m/min

- Temperature: 180—200℃

- Air pressure: 8—1.3Mpa

Spec of Motor:

- Main Motor: 15kw

- Nominal voltage:380V 50Hz Continuous (S1) working Type

CGM-F Triplex Gluer

Structure and Features:

- After the glue roller surface quenched, bore machining, surface grinding and doing balancing engraved pit style textured, coating evenly, consume less glue.

- Glue roller rotation frequency motor control, the inverter control ensures glue line speed and duplex roller synchronous machines, and can operate independently.

- Electric adjustment digital glue. Automatic cycle for glue, glue avoid sedimentation and viscosity stability.

- Pneumatic presses structure, trimming the gap by the electric. Three layersare used independently variable frequency motor drive.

- Sided machine speed signal measurements taken in order to achieve its synchronous operation. Man-machine interface display, easy operation.

Common Spec:

- Preheater cylinder temperature range: 150—180℃ Steam pressure: 0.8—1.2Mpa

- Pneumatic system: 0.4—0.7Mpa

Spec of the rollers’ diameter:

- Glue roller:Φ269mm Glue amount adjusting roller:Φ140mm

- Down preheater roller:Φ402mm Up preheater roller: Φ374mmPaper roller:Φ86mm

Spec of Motor:

- Glue quantity adjustment motor:250W

Nominal voltage:380V 50Hz Short time (S2) working Type - Glue pump motor: 2.2KW

Nominal voltage: 380V 50Hz Continuous (S1) working Type

Triplex OHB Conveying Bridge

Structure and Features:

- The Main Frame is connected with channel steel, and angle steel.

- With Protecting Handrail on both sides and safety pedal, the operation side is installed with safety ladder, to make sure the safety and convenience of the worker.

- Vacuum suction tension control, suction pipe with adjusting valve,drawfan power can be adjusted freely.

- Correct the positionby double guide posts ,correct parts are driven by screw , fast and accuracy to position, steady to move.

Spec of the rollers:

- Paper feeding rollers & tension rollers:Φ127mm transport rollers:Φ110mm

- Main tension drive rollers:Φ127mm paper pass rollers and paper guide rollers:Φ110mm

- Paper feeding rollers with belts:Φ110mm

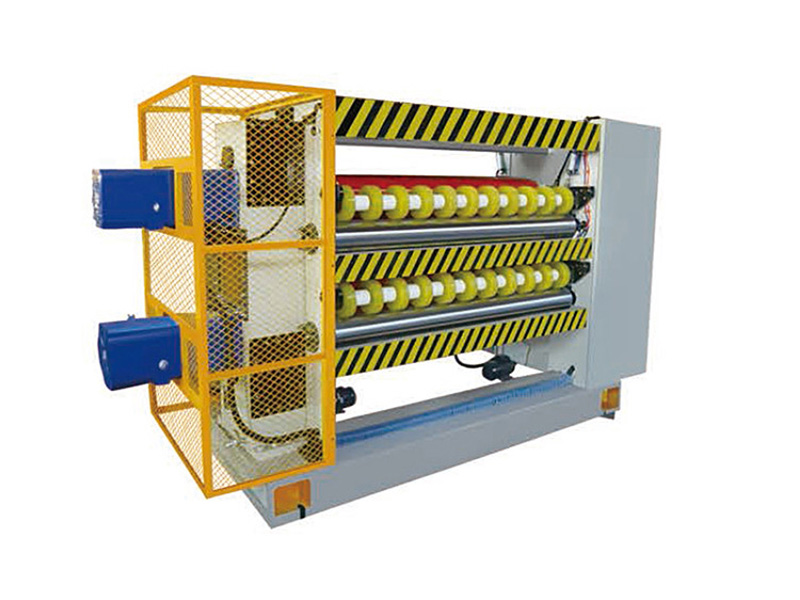

HPM Double Facer

Structure and Features:

- Hot Plates’ surfaces is grinded and then chromed plated,width:600mm.total 16 pieces of hotplates

Hot plates are made by container plates, can pass the national first level pressure container standars - Hot plates adopts the compressed press rollers structure.Pressure roller lifting adopt pneumatic structure

- Up convey belt left and right correct by auto with both sides, tension adjusting system; downbelt manual small amount adjust.

- Drive rollers’ surface is wrapped by rubber, Y shape structure,with middle height,to make sure the board can be out smoothly

- Main drive motor: Variable frequency motor, high force when low speed start, high speed adjusting range, steady to use,easy to mend.

- Hot Plates’heat pipe piecewise control temperature.

- Up belt adopt double cylinder S type tensioning device

- Under belt adopt S type manual correcttensioning device.

Common Spec:

- Temperature requirement: 160—200℃ Steam Pressure :0.8-1.3Mpa

- Air pressure:0.6—0.9Mpa

- Cool shaping length: 4m Heating plates amount: 16pieces

Spec of Motor:

- Main Drive Motor: 37kw Frequency

- Nominal voltage: 380V 50Hz Continuous (S1) working Type.

FTKM Electric Slitter Scorer

Structure and Features:

- Overcome the phenomenon of collapse the board when crop, smooth cutting, and the quality is improved

- The machine can move lift and right, adjust by cycloidal reducer.

- Cutter and line pressing adjustment convenient, error is ±0.5 mm, with automatic sharpening device

- 5blades8lines type, blade is made of tungsten alloy steel, life is more than 30,000 m

Technical parameter:

- Max. width:2200mm

- Specification: 5 knives 8lines

- Min. Cut width:135mm

- Max cut width:2250mm

Motor:

- Knife motor:0.4KW

- Knife driver motor:5.5KW

NC-S120 Cut Off Machine

Structure and Features:

- Cutting length:500mm-9999mm.Cutting precision:±1mm.

- Knife shaft gear using precision forging steel material high frequency quenching, lateral clearance transmission , adopt the keyless connection mode, high driving accuracy.

- Helical knife structure,type sawtooth knife,decrease cutting obstruction,low noise.

- Balance treatment, high quality alloy steel for blade shaft,which helps to keep it good stability.

- Sun-shape wheels press cardboard in the front and the rear conveyer.The transporting is stable and with even pressure,which avoid jam caused or broken cardboard.

- Precision adjustable gap gear, ensure blade precision engagement, running balance.

- Machine base and wall panel adopt the grey cast iron, good rigidity, strong vibration resistance.

- The servo controller control the servo motor, Taiwan Eview 10.4 inch touch screen

Technical parameter:

- Min. cut length:500mm 2. Max cut length:9999mm

- Cut precision: uniform velocity ±1mm, non-uniform velocity ±2mm

Motor:

- Main motor:12.5kw Ac synchronous servo

- Feeder motor:3 kw(Frequency control the speed)

- Lubricating oil pump motor:0.25kw

Sheet Delivery Machine

Structure & Features:

- Weld by 14 # channel steel, electric to adjust the size of the board, pneumatic to control the the output on transverse direction, output speed can be adjusted electrically.

- Corrugated sheet can be controlled output by foot switch when the mount or height of stacking corrugated sheet reaching the needs.

- Longitudinal joint paper adopt wide conveyor belt conveyor.

Common Spec:

- Max length of stacking:3000mm

- Max height of stacking: 200mm

Spec of Motor:

- Main feeding frequency variable motor: 3KW Frequency conversion motor

- Transverse direction motor: 1.5KW Three-phase asynchronous motor

- Traveling motor: 1.5KW Three-phase asynchronous motor

GET A FREE QUOTATION

Related Products