professional carton manufacturer auto high speed printer die cutter machine LANLING

auto high speed printer die cutter machine china supplier

- Source of goods manufacturer, 18 years of production experience and guaranteed after-sales service.

- Competitive prices, factory prices, no links to trading companies.

- Intelligent equipment is easy and fast to operate. improve the change order time .

- Auto printer is our main product.

- Customized according to customer requirements.

- This production line is a multifunctional production line for printing, die-cutting, gluing and bundling.

- CE certification.

carton priduction line auto flexo die cutting machine with folder gluer strapper line

JL-2600 The design and manufacture carton automatic glue machine conforms to printing, slotting, folding, bonding and stacking. It has the functions of carrying, applying glue, folding and forming several layers automatically. Using PLC control, touch screen operation and pre-storage and management of orders. Its high-speed production capacity, fast-changing orders and good stability can meet the shorter and shorter delivery cycle requirements of our carton customers.

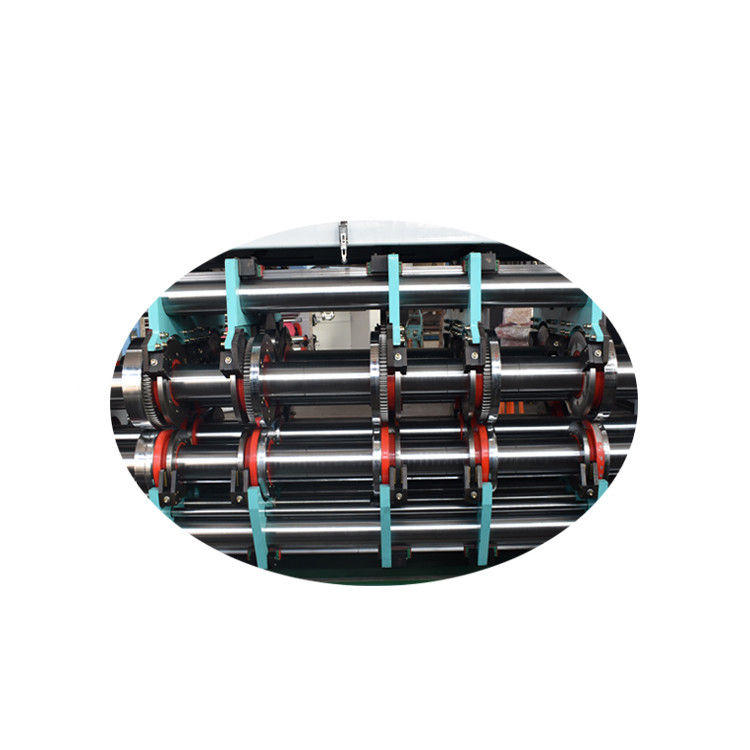

Glue, transfer unit

- u Computer-controlled automatic setting of the fuselage and glue application position

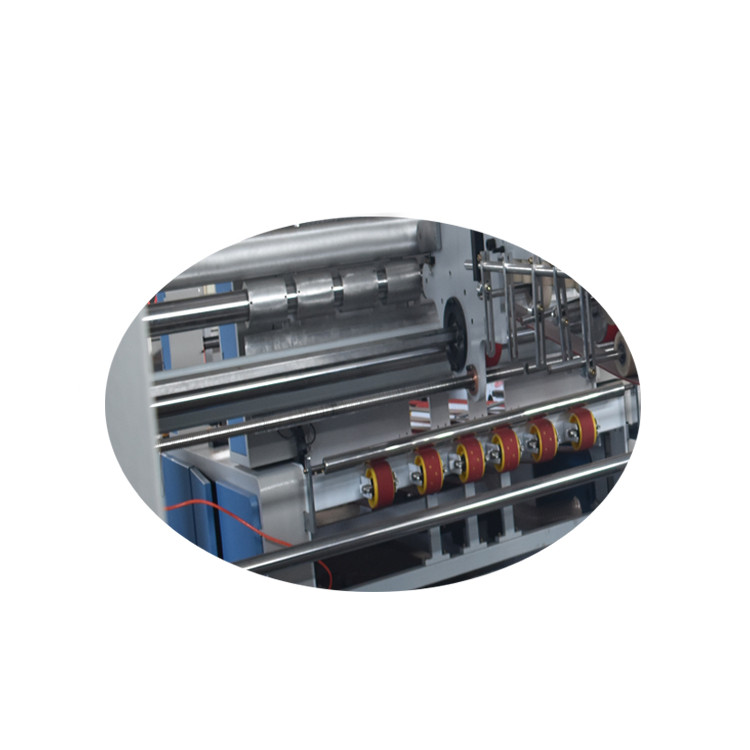

- u The paper inlet is powered by an electric hair roller and high-pressure air blower to clean the cut corner waste edge, and completely remove the waste edge

- u Pneumatically adjust the tension of the conveyor belt, automatically release the conveyor belt during paper jam detection

- u Spring-loaded conveyor wheels, no need to adjust the pressure of conveyor belt and cardboard

- u Secondary crimping: the side pressing wheel re-crimps the passing cardboard to make the folding more accurate

- u Optional Italian ERO, American VALCO and other well-known brands of glue spraying system, without any settings, automatically adjust the length of the glue line

Folding and correcting unit

- u Strong suction fan to ensure the accurate transmission of cardboard during the conveying process

- u The speed of the right and left correction belts can be adjusted separately to reduce the occurrence of scissors difference

- u The main power adopts frequency conversion motor to ensure the synchronization with the printing machine

- u Paper jam checking device, automatic emergency stop when cardboard conveying is not smooth

- u All power is driven by synchronous belt, with simple structure, low noise, stable operation and low vibration

Counting and pushing unit

- u Counting and pushing out part of cardboard falling way

- u Three groups of servo motors together constitute the functions of accurate counting, accumulation and output under high-speed operation

- u Computer control automatically sets the number of palletized cartons

- u Strong wind pressure device makes the glued cardboard fall smoothly

- u Fully aligning and correcting device, effectively improve the phenomenon of scissors difference

- u The rear baffle can be adjusted automatically or manually according to the specifications of the cardboard

- u Automatic emergency stop when the cardboard is not discharged smoothly

- u Pneumatic paper pushing mechanism pushes the stacked cartons at high speed

- u Electric left and right moving device (aligned to the center)

Main technical parameters of folder gluer unit:

| name | FG-3100x1200 |

| Max working speed (pcs/min) | 200 |

| Min folding size A mm | 240 |

| Min folding size B mm | 200 |

| Minimum spacing mm | 440 |

| The min width of cardboard E mm | 400 |

| The max cardboard size E mm | 1400 |

| The min cardboard H mm | 880 |

| Max feeding size H mm | 2800 |

| Size of F mm | 20-60 |

| THK mm | 1.6-9 |

Automatic PP strapping machine

1.Usage and characteristic:

Automatic strapping machine is mainly used in automatic sticky box machine/output after automatic strapping automatic order box machine, the machine by turning, taken together, pressurized banding.Using PP strapping, strong, do not rebound, paper edge damage.The whole process automatically, without human intervention, can save a lot of artificial cost.Such as color, paper products factory packaging equipment for increasing the income of enterprises and reducing consumption.

2.Main structure

The machine contains four parts: Receive board and turn part, clear up and patting part, delivery part, pressure strapping part.

3.Each part characteristic and function

(1)Receive board and turn part

- Smoothlyreceive cardboard before prior conveying.

- Double touch type steering, will be 90 degrees of corner cardboard.

(2)clear up and patting part

1, can be adjusted according to different specifications carton size.

2, arrange positioning automatically four direction taken together, and then delivery.

- delivery part

After finishing send carton smoothly, improve the work efficiency;

(4)pressure strapping part

1, pneumatic pressure will be more than one solid board.

2, PP belt automatically, the elastic can be adjusted, paper edge damage light.

3, automatic adaptation cardboard size.

4, photoelectric sensing detection strap position.

5, 1~2 Road, the use of knob switch

6, strapping automatically after delivery.

(5)work procedure

Receive paper and ture——→pat and clear up——→delivery——→press and strap ——→finish delivery

4 .Technique parameter

1.Max.paperboard: 1200 x 1200

2.Min. paperboard : 300 x 400 working speed: 8.5 bundle * 2 / min

- packing line total power (including steering machine, box machine, pressurized power packing machine): 3KW;

- power supply: three phase five wire AC380V (1+10%) 50Hz;

- steering machine (L2210 W2050 H1350);

- close box machine (L1800 W2050 H1350);

- packer (L1500 W665 H1792) working ability: 10-18 pieces / points;

- working environment: relative humidity is less than 90%, temperature is 0-40 degrees Celsius, noise is less than equal to 75dB (A);

- bandwidth 5. 12 .mm

- disc specifications: the inner diameter of the band core of the band 200mm-210mm, the outer diameter of the band 400-450mm, the band width 175-190mm;

- bonding method: thermal fusion;

- bonding method: bottom bonding, adhesive surface more than 90%, adhesive position deviation less than equal to 2mm;

- bundle tightness: 0-45Kg;

- gas source pressure: 0.5-0.8MPa; 14. roller material: stainless steel;

- cylinder diameter: 50mm, wall thickness: 1.5mm;

- transmission speed: 0-50m/min

- Overall dimensions: 5800 x 2300 x 1800 mm

- Power supply : three phase four phase distribution (three-phase 380 v + zero).