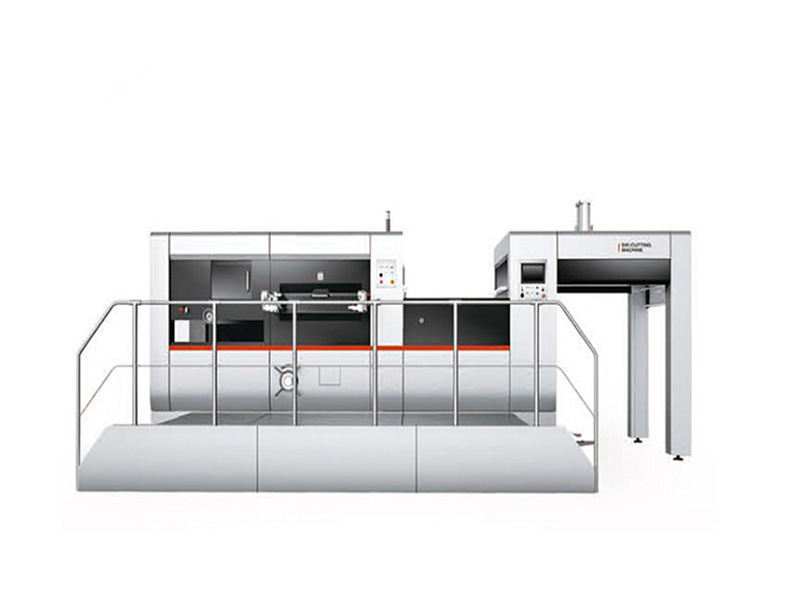

Semi Automatic Cardboard Platen Die Cutting Scoring Machine

Cardboard platen die cutting scoring machine china manufacturer

1.manual feeding cardboard.High cost performance.

2.Equipped with automatic paper loading truck.

3.The R & D technical team keeps updating and improving. Domestic advanced level.

4.Central positioning system, simple and fast formwork loading and unloading.

5.Used for cartons, cartons, handbags, trademarks, decorative materials, etc

6.Professional carton equipment.manufacturing experience for 20 years.

Features:

MY1200/1300/1500/1650 semi-automatic die-cutting and creasing machine is professional for cutting offset print box. combining the advantages of domestic and foreign products. There is high strength gripper,advanced open gripper structure can adapt to a variety of signal paper, corrugated board: Front, back and side gauge assure the cutting accuracy .It also has intermittent mechanism with high precision, sensitive pneumatic clutch, pneumatic lock plate , PLC, HMI. Working speed, paper account, total running time are very clear on the screen: Input and output monitor make it easy to exclude the breakdowns. It adopt the frequency converter to the main motor, using for stepless governor. There are many protection sensor to ensure the workers safety. What’ s more, the front and back pressure can be adjusted individually, manual running is very convenient, die-cutting without clipper margin can be realized.

Components and functions:

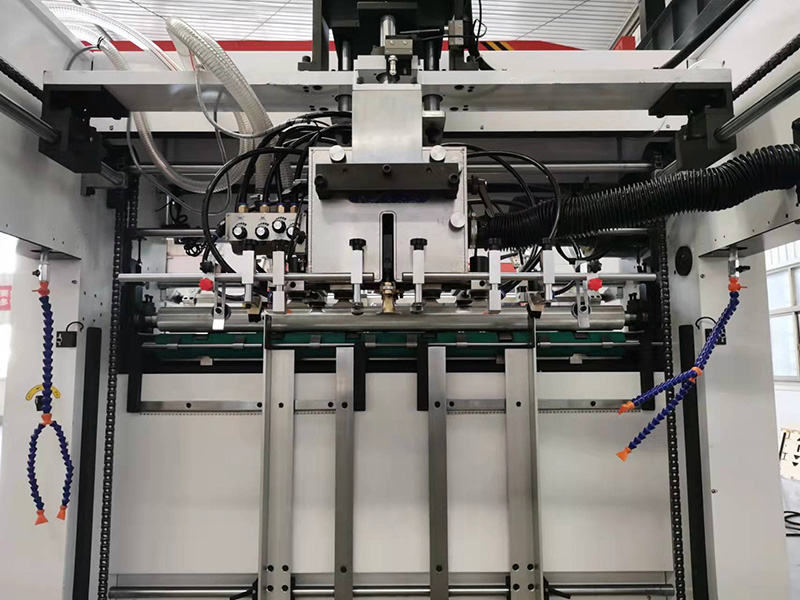

- Feeding mechanism

Paper feeder structure: suitable for all kinds of paper, high-speed and stable, easy to adjust. - Positioning part:

Front guide plate: high positioning accuracy. Four sets of precision optical fiber switches (Riko brand in Taiwan) check that the paper is in place to avoid paper waste.

Side guide rail: you can select the side guide rail according to different products without replacing parts, which is convenient and fast to adjust. - Die cutting part: the die cutting pressure can be adjusted as a whole, or the edge of the front clamp can be adjusted separately. The manual reducer is convenient and labor-saving.

Gripper: the gripper is made of high-strength hard aluminum alloy by precision casting. It has good rigidity, light material, small inertia and high strength. It can transfer paper accurately and stably during high-speed operation.

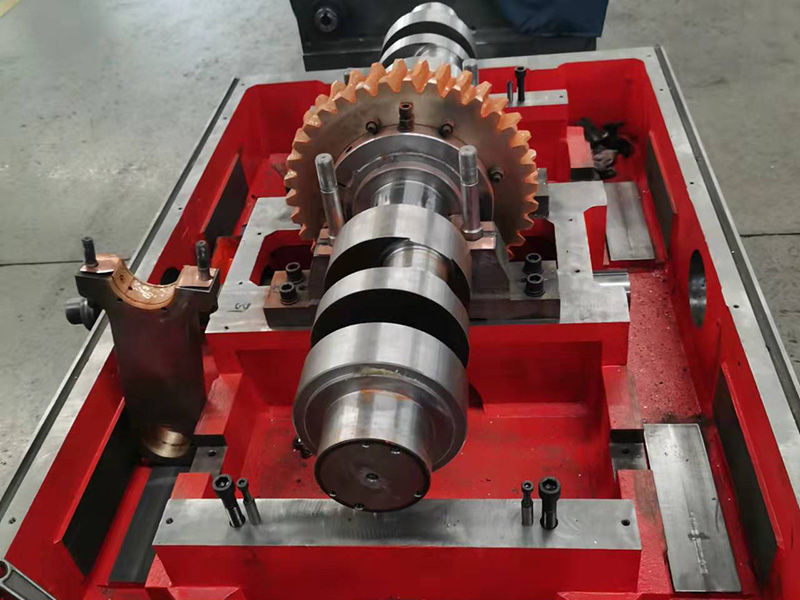

Transmission structure: new transmission design, high speed and precision die cutting

Pneumatic clutch brake: the transmission torque is controlled by adjusting the air pressure, with low noise and good braking performance. - Paper receiving part: automatic quantitative paper receiving.

- Electrical control part: motor, PLC and man-machine interface, electronic control system and various safety protection devices.

Motor: imported Fuji frequency converter stepless speed regulation motor is adopted.

PLC and man-machine interface: digital display of the working speed and state of the machine. The main motor is controlled by the frequency converter and stepless speed regulation makes the operation more stable.

Electrical control system: microcomputer control process, automatic control and real-time detection from the whole process of paper feeding, paper feeding, die cutting and paper receiving. - Lubrication system: forced lubrication system and timed lubrication system.

The Machine technique parameter:

| Model | MY-1200 | MY-1300 | MY-1500 | MY-1650 | |

| Max.Paper Size | 1230x850mm | 1320X940mm | 1510x1120mm | 1670x1250mm | |

| Min.Paper Size | 350x450mm | 400x500mm | 450x550mm | 500x550mm | |

| Max.Die-cutting Size | 1210x830mm | 1300x920mm | 1490xllOOmm | 1650x1200mm | |

|

The minimum size in mouth |

8 | 8 | 8 | 8 | |

|

Max.Die-cutting Pressure |

300N/cm2 | 300N/cm2 | 320N/cm2 | 350N/cm2 | |

| (mm) | Cardboard | 200-2000g/m2 | 200-2000g/m2 | 200-2000g/m2 | 200-2000g/m2 |

| Corrugated paper | 8mm(max.thickness) | 8mm(max.thickness) | 8mm(max.thickness) | 8mm(max.thickness) | |

|

Die cutting precision |

±0.1 | ±0.1 | ±0.1 | ±0.1 | |

| (sheets/h)Max.die-cutting Speed | 5000 sheets/h | 5000 sheets/h | 5000 sheets/h | 5000 sheets/h | |

| Max.Feeding Pile Height | 1400mm(above the level) | 1400mm(above the level) | 1400mm(above the level) | 1400mm

(above the level) |

|

| Max.Collecting Pile Height | 1200mm(above the level) | 1250mm(above the level) | 1250mm(above the level) | 1300mm(above the level) | |

| Total Power | 11KW | 13.5KW | 13.5KW | 20KW | |

| Weight | 13T | 14.5T | 17.5T | 21T | |

| Dimensions | 4200x2200x

2250mm |

4200x2250x

2250mm |

4200x2300x

2250mm |

5200x2450x

2250mm |

|