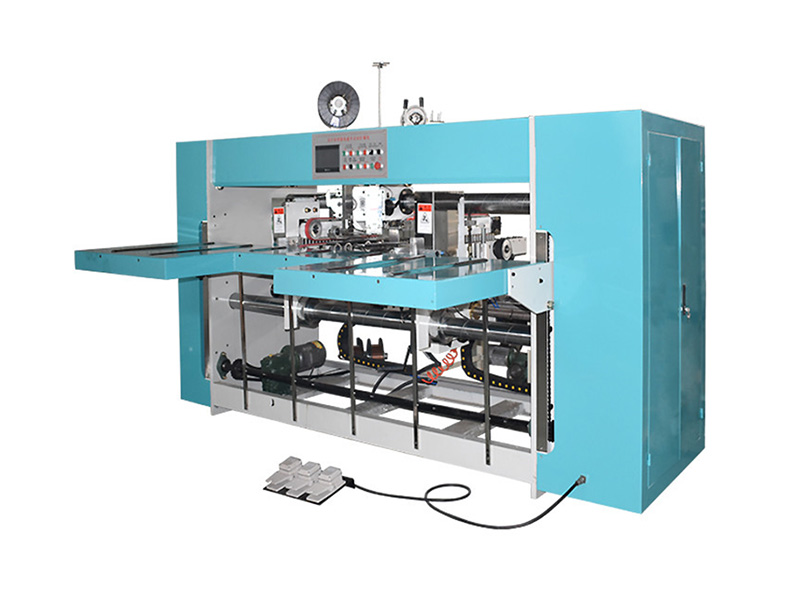

Stitcher Corrugated Machinery Semi Auto Carton Box Stitching Machine

Semi auto carton box stitching machine china manufacturer

- lt can nail single nail,double nail,Strengthen nail completed in one-time,can be suitable for different kinds of customer requirements of nails.

- It can be changed size quickly in one minute,can be operated easily and not had to experience.

- It is man-machine interface control for convenient operation.

- Back-automatic counting.The finished products done can be sent to the end of conveyor by setting the number(1-99).

- Semi-finished products nailing to the finished products displayed only need two operators. This can operate simply and reduce wages.

Feature:

- Max machine speed:500stitches/min

- Stitching pitch:30-120mm

- Auto counter and stack

- 25mm for first stitch

- 4mmWidth*0.6mmThick

- Max grooving nail length:600mm

- Quick order change easily by touch screen in 1 minute

- Adjust size by auto control, error be showed on touch screen

- Be suitable for 3 ply 5 ply, also for box without cover

Share This Page

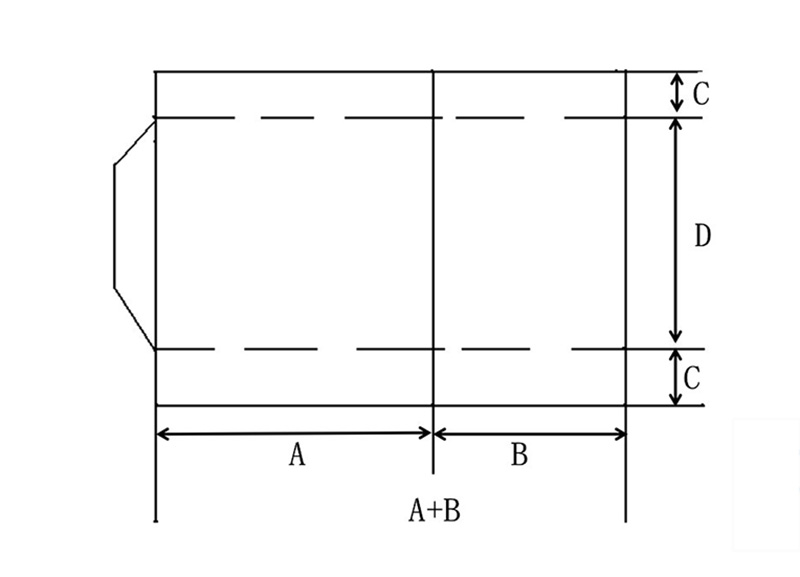

Main technical parameters:

| Models and parameters | 2500 | 3000 |

| (A+B)*2(mm)The biggest paper size | 4000 | 4800 |

| (A+B)*2(mm)Minimum size of paper | 1060 | 1060 |

| AMM The biggest carton long | 1850 | 2350 |

| AMM The smallest carton long | 350 | 350 |

| BMM The biggest carton width | 1000 | 1200 |

| BMM The smallest carton width | 180 | 180 |

| (C+D+C) The biggest paper high | 2500mm | 2500mm |

| (C+D+C) Minimum high paper | 380mm | 380mm |

| C(mm) The biggest shake cover size | 560 | 560 |

| C(mm) Minimum rock cover size | 50 | 50 |

| D(mm) Maximum height | 2000 | 2000 |

| D(mm) The minimum height | 150 | 150 |

| (mm) Maximum width of the tongue | 45 | 45 |

| mm Nail is apart from the | 30-120 | 30-120 |

| Pin number | 1-99 | 1-99 |

| (次/min) Nailing speed | 500 | 500 |

| (T) Machine weight | 2.5 | 3 |

Introduction :

this is a development of the new company, With high efficiency, the more accurate the high-speed operation and high efficiency nailing molding machine, Import double servo drive, precision accurate, mechanical rotating part decreases, Can effectively reduce the mechanical failure,

It can promote the finished products, products and expand the product’s characteristics, and improve the production management is more elastic, Arrange production process, at the same time can save time and cost of production。

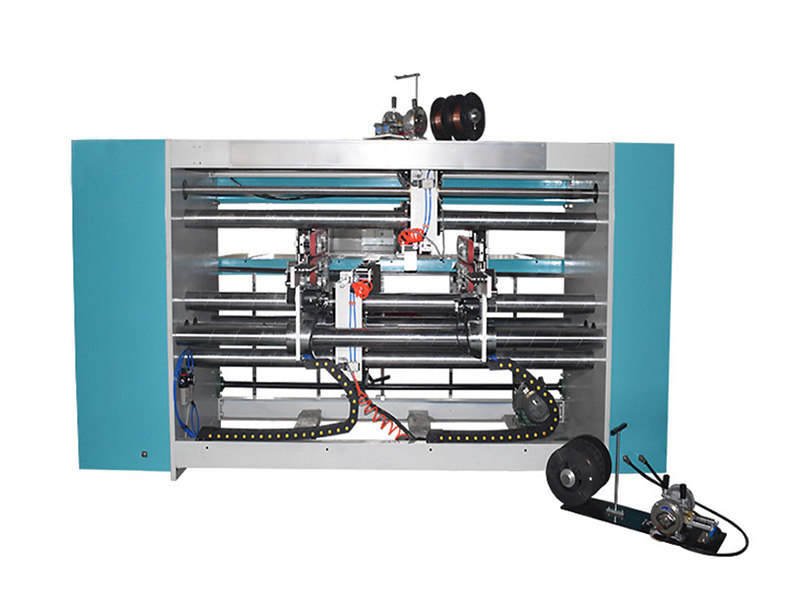

- imported double servo drive, precision accurate, mechanical transmission part decreases, can effectively reduce the mechanical failure rate.

- touch screen operation, the parameters (nail distance, pin number, nail type, tailgate) transform is convenient and fast.

- the whole control system adopts Siemens PLC control system.

- electric tailgate, adopt the stepping motor drive, precise size, frequency conversion size more convenient and quick.

- control box the full contactor for Siemens brand.

- bottom die block, blade adopt the Japanese tungsten steel production (wear).

- whole the pin head all adopt the special steel production, the computer precision machining.

- can nail single nail, double nail, strengthen nails (two head is double nail, and the middle part is single nail) one-time finish, can suitable for different customers on the nail of different requirements.

- transform carton size and adjust carton nail distance, it takes only one minute to complete, and greatly save time convenient operation.

- front end paper feed department automatic counting, Feeding paper table with opto-electronic devices,when feeding paper automatically rise.

- posterior segment with automatic counting function, completes the finished product number of sheets can be directly set number (1-99), batch sent to the conveying machinery end, Convenient packaged banding.

- mechanical speed: 500 nail/minutes.

- rubber wheel clearance adjustment: in the panel on the left button, rotating button clockwise rotation is rubber wheel clearance reduce:make the button clockwise rotation is rubber wheel clearance increase, In order to provide direct input in the thickness of the carton, the machine automatically adjust thickness.

- carton width adjustment: the left and right baffle move to both sides, will board folding put into nailing position were moving around on both sides of the carton board close to leave paper 2 mm gap, then fixed damper.

- touch screen operation, the parameters (nail distance, nail number, nail type, tailgate) transformation convenient, quick, PLC control system,7 inch screen.

- electrical component Siemens ,schneider,and Omron brand.

- the pin head all adopt the special steel production.

- nail line with automatic alarm device.

- electric tailgate, adopt the stepping motor drive, precise size, frequency conversion size more convenient and quick.

GET A FREE QUOTATION

Related Products